One of the keys to the success of hydrogen as a vehicle fuel will be fueling infrastructure. Nikola Motor is working with Nel Hydrogen Fueling, which will build the initial hydrogen stations for deployment of Nikola’s hydrogen-electric trucks. Without a fueling infrastructure, Nikola’s vision of long-haul Class 8 hydrogen-electric trucks will come to an abrupt end.

With the two companies working together, they have created a path forward that depends on the trucks and the stations coming online at the same time, starting at locations on the West Coast. The first station is already operational, in Phoenix, which Jesse Schneider, executive vice president of hydrogen and fuel cell technology for Nikola Motor, said was a “demo” station.

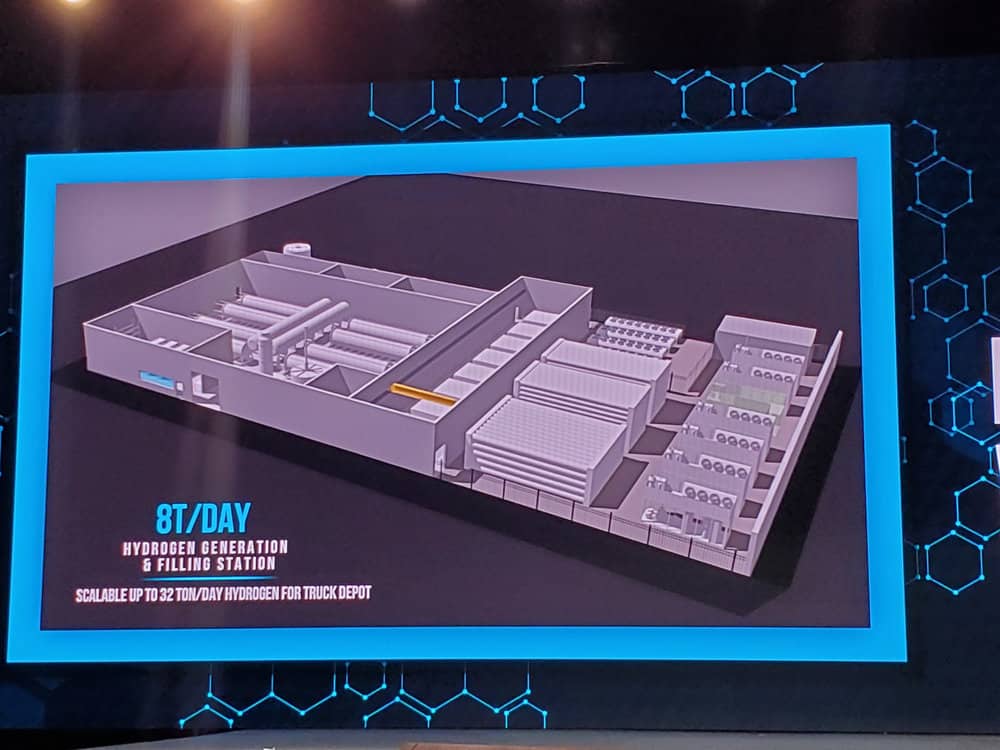

Additional eight-kilogram ton per day stations will start to come online in 2021 with a ramp up in stations starting in 2022, eventually leading to 700 stations in the U.S. Test stations will begin to arrive in California next year for a customer trial.

The stations themselves will be able to produce their own hydrogen and will include solar panels on the roof tops. Each station is being designed to require between 7 and 10 acres of land, although work will be done to try and minimize that requirement.

The deployment strategy “solves the chicken-and-egg problem because you install the station at the same time you deploy the trucks,” said Jon Andre Lokke, CEO of NEL ASA, Nel Hydrogen’s parent company.

Schneider added that station design includes 8 heavy-duty fueling pumps and 4 light-duty fueling pumps for automobiles, with each station capable of filling 150 trucks and 200 cars per day.

Nikola expects the cost of the hydrogen fuel to be about 4 cents per kilowatt hour for electricity to produce, resulting in a retail cost of about $6 per kilogram. Lokke said that is about half of what it currently costs in California. Part of the cost remaining low is because the stations will produce much of their own hydrogen, so transportation costs have been eliminated, as have lifecycle emissions.

The two companies have also joined a consortium, formed in February, that hopes to develop global standards for hydrogen fueling infrastructure. The Hydrogen Suppliers & Fuel Cell Electric Vehicle (FCEV) Automakers, Air Liquide, Hyundai, Shell and Toyota are also part of the group.

The initial testing will feature pre-commercial 70MPa hydrogen heavy duty vehicle high flow (H70HF) fueling hardware for future Class 8 (40 ton) trucks. The industry group has created specifications for the fueling nozzle, vehicle receptacle, dispenser hose and breakaway device components.

“The goal is to enable interoperability so that any HD FCEVs can fuel at our hydrogen stations and we can fill at any of theirs, just like diesel today. This is a big first step,” said Schneider.

Hydrogen itself is seen by some as an ideal fuel source. According to DriveClean, a California government website dedicated to hydrogen, the fuel produces zero emissions and compares favorably against combustion engines.

“Unlike the controlled chemical reactions in batteries and fuel cells, gasoline combustion is marked by a series of uncontrolled chemical reactions that produce many undesired compounds. NOx, SOx, and particulate emissions are all undesired products of combustion that negatively affect air quality,” the site claims. “The uncontrolled combustion of gasoline also reduces how efficiently engines transform chemical energy into power. A conventional combustion engine uses less than 20 percent of the chemical energy in gasoline, which means more than 80 percent of the fuel is ‘wasted.’ In contrast, a fuel cell converts up to 60 percent of the chemical energy in hydrogen to drive the vehicle. Therefore, a fuel cell electric vehicle is potentially 3 times as efficient as traditional combustion vehicle and virtually pollution-free.

“Fuel cell electric vehicles achieve the beneficial characteristics of both conventional and battery electric vehicle,” it went on. “The combination of these desirable characteristics makes fuel cell electric vehicles an attractive advanced vehicle option for drivers that value long range, fast refueling, and zero-emissions.”

“Hydrogen as fuel for the heavy-duty transport sector is showing great promise and traction, and we are now in the process of developing the next generation, high capacity stations for this segment. In order to enable commercial success for this segment, standardization of fueling hardware is a key,” said Jørn Rosenlund, SVP of Nel Hydrogen Fueling.

Mark Russell, president of Nikola Motor, explained to FreightWaves earlier this year why hydrogen is the right solution.

“We will not be using any hydrogen that comes from hydrocarbons. It’s all electrically generated. We’ll take all of our electricity from renewable sources. That’s the big part of this,” he said. “The trucks are fun to show. But the more important part of this is the hydrogen supply chain that we’re proving out – it’s about hydrogen as a way to store fuel, and balance grids and get renewables into the grids without causing problems. Because that’s the problem with renewables; they only generate when the wind blows or sun shines, and what do you do with them when you don’t need it? You have to store it.”

Russell said that making hydrogen is the answer because it can be stored for long term.

“Once you’ve made hydrogen and stored it, it can sit there forever,” he said. “It doesn’t degrade. It doesn’t leak. And when you turn it back into electricity it becomes water. It’s an elegant, beautiful, simple solution for storing energy, so much better than batteries. You break down water; you put it back together.”

Nikola plans to install up to 700 hydrogen fueling stations around the country by 2028. The plan starts with meeting customer needs and building from there, Russell said.

“For the retail, we will start on the geographies and the routes that make most sense for our customers,” he said. “Internally we have very specific plans about which geographies and which customers, and they’re the ones that will get the coverage first. By the time we are producing at a rate that we need nationwide coverage, we’ll have a nationwide network of stations. We will also be providing dispensing equipment and everything for a station but the retail part for dedicated fleet customers.”