Startups seeking to commercialize autonomous freight modify existing trucks with the goal of removing the driver. Newcomer Solo AVT thinks a clean sheet approach — a cabless “battery on wheels” running hub to hub with teleoperation at either end — is a better answer.

Electrification. Autonomous trucks. A better way?

In covering trucking electrification and autonomy, it can be easy to follow the quarter turns and occasional breakthroughs from the startups that position themselves as most likely to succeed. Legacy names like Daimler Truck North America, Volvo Group and startups like Nikola, Hyliion, TuSimple, Aurora Innovation and a dozen more.

Covering them means overlooking outliers that lack a track record. That group may be just as large. One example is Solo Advanced Vehicle Technologies, founded by former Waymo, Tesla and BMW engineers. They claim legacy and startup manufacturers aim too low to meaningfully transform the $700 billion trucking industry.

“Yes, they’re talking about electrification. Yes, they’re talking about autonomy,” Solo CEO Graham Doorley told me. “But it’s not the main push of what they’re trying to do. A 150-mile [or] 250-mile range is never going to get there.”

Solo attracted some media attention in March when it announced its SD1 Heavy platform. It is designed so AV companies could integrate their self-driving software and sensor suites.

We passed at the time. Rationale? In a space where billions of dollars have been invested, Solo has raised just $7 million. It plans a series A funding round June 1 and claims potential investors are lining up.

So, when Solo offered us the first look at computer-generated images and videos in advance of next week’s Advanced Clean Transportation Expo, I said, “OK, let’s talk.”

A clean sheet for a startup

Before founding Solo last September, Doorley spent eight years as a senior engineer at Waymo, formerly the Google self-driving car project where he was a mechanical engineer. Doorley has a master’s in mechatronics from Stanford and a bachelor’s in physics, materials science and engineering from Carnegie Mellon University, an autonomous vehicle hotbed.

He advocates a clean sheet approach to electrifying trucking for autonomy. Forget about using today’s equipment to create tomorrow’s transport system. You’ve got to start over to get it right.

“You won’t get there if you don’t design a ground-up new platform, which is what we’re doing,” Doorley told me. “We’re what’s needed now that we don’t see coming, that’s not being built. It’s not even being thought about.”

Et TuSimple

Even TuSimple, Doorley contends, focuses too much on massive amounts of computer software performing hundreds of trillions of calculations a second. That doesn’t matter without the right physical platform in which to integrate. As the first to go “driver out” in 10 pilot runs, TuSimple arguably leads the race to autonomous commercialization even with a delay to 2025.

And what of TuSimple’s manufacturing partner Navistar? Though it claims to be powertrain agnostic, the Traton Group subsidiary lacks the bandwidth to design a truly electric vehicle for autonomy. And Traton pledges to put nearly $3 billion into electrification by 2026. A ground-up Navistar International LT running TuSimple’s autonomous system falls short of what’s needed.

“I saw this in Waymo, which is far and away the largest and most well-funded of the autonomy companies. They’re kicking it down the road. They’re saying, ‘We don’t really care right now because we need to focus on the software.’”

Waymo Via integrates its fifth-generation software and hardware into Freightliner Cascadia Class 8 trucks from Daimler Truck North America. DTNA has a separate effort with independent subsidiary Torc Robotics.

“If you take a Cascadia and say, ‘I’m going to make 500 miles of range,’ good luck,” Doorley said. “You’re not going to be able to do it because there’s too much that has to change. You’re Band-Aiding on solutions. And that’s crippling the industry right now.”

This looks vaguely familiar

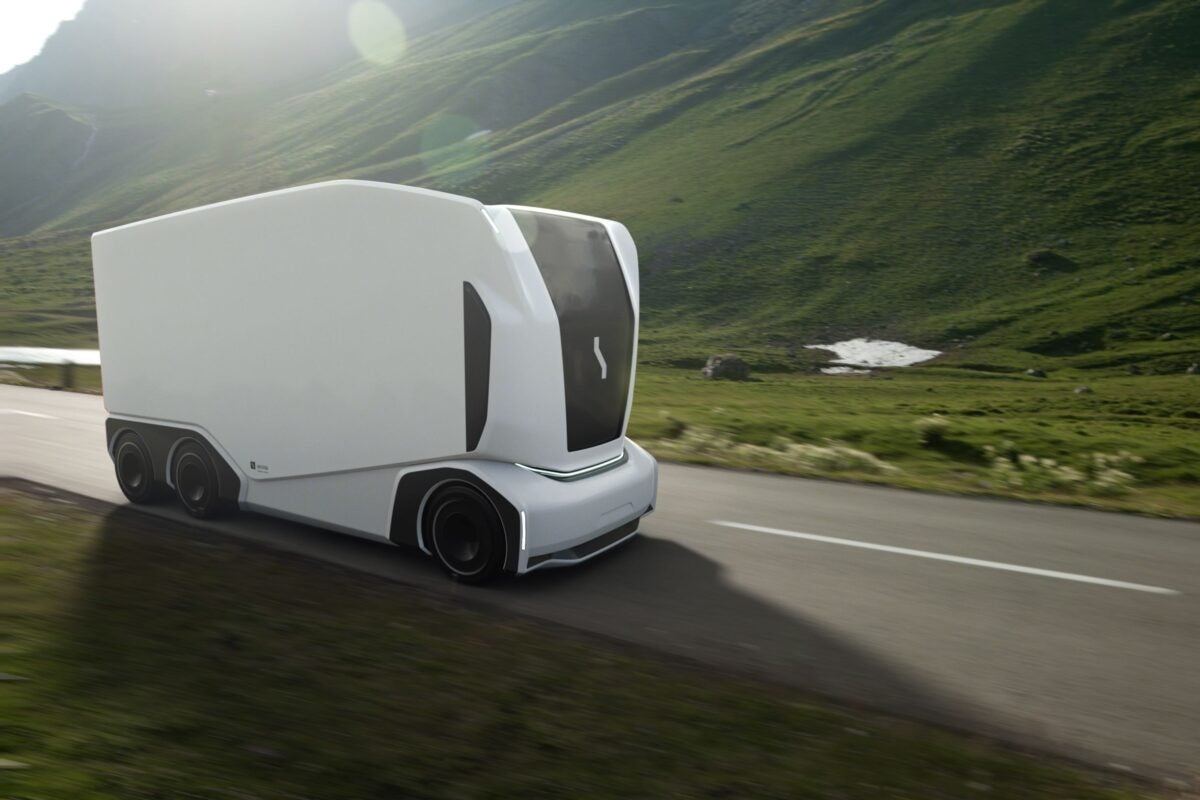

Solo has a pair of mule vehicles retrofitted by Unique Electric Solutions to run on batteries. The design of the SD1 resembles the electrically powered remote-controlled Einride pod from Sweden. Volvo’s cabless autonomous and teleoperated Vera prototype operates on the same principle.

The SD1 tech specs include tires designed to minimize rolling resistance, exterior lighting to communicate to pedestrians and other road users, a unique sound signature, a modular design for easy servicing — read uptime — and multispeed tandem e-axles with integrated electric motors. The truck is compatible with fast chargers and existing charging networks.

“What we’re designing is really a battery on wheels,” Doorley said. “The entire platform is designed around a battery system.” No cab. No drivers. Just teleops at either end of the hub. The SD1 works with any trailer and meets standard dock heights

Is a rolling battery a better solution for autonomous trucking?

The sleek aerodynamic lines that conventional truck makers market as their best ever effectively resemble bricks inside a wind tunnel.

Alpha model testing of the SD1 is planned within two years, assuming it gets the funding it expects. Figure production sometime before the end of the decade based on a typical four-year vehicle development timeline.

Solo won’t share how much battery mass it takes to travel more than 500 miles on a single charge. It is still working on its frame design and “everything else” to determine the size of the battery.

“Physics is physics, right?” Doorley said. “So it’s going to be the biggest battery on the road.”

Thanks for reading. Click here to get Truck Tech via email on Fridays.

Alan