Safety is important. Yet, we can do safety research and development a lot faster.

It’s timely to ask why the regulatory process takes so long. The release of the World War II movie “Midway” later this week suggests we rethink our pace.

Why?

Because our parents and grandparents back in 1942 took only a few short months to answer the Japanese attack on Pearl Harbor (December 7, 1941) with targeted responses. How? They used ingenuity, intelligence assessments, and a passion for getting on with the task at hand.

The results – Tokyo and a few other Japanese cities were symbolically bombed within about five months of Pearl Harbor. Furthermore, four Japanese aircraft carriers – the pride of the fleet – were sunk at the battle of Midway within six months and three days of Pearl Harbor.

Today in transport logistics, our society seems to lack that “sense of urgency.”

As one example. it now takes regulatory agencies as long as 18 to 24 months to complete an accident investigation report. Why so long? It’s a mystery.

Regulatory lag has a direct impact upon the commercialized use of abundant natural gas as a much more environmentally clean fuel.

There is no question that natural gas is an abundantly available fuel source. Some estimate that there is a 200-year supply of natural gas in the U.S. alone.

Getting the natural gas to market overland at an attractive price is the issue, so long as there are few pipelines available. Rail freight could be a viable business solution. But in the USA, railways are not yet a player in the natural gas supply chain.

What is LNG?

Natural gas from a well head consists of several elements, primarily methane (CH4). Methane in a natural state is a colorless, odorless, tasteless and non-toxic gas.

Liquefied natural gas (LNG) is processed natural gas that is mostly methane cooled down to a liquid form for storage or transport. Once liquefied by this cooling process, LNG takes up about 1/600th the volume it had in its gaseous state.

LNG does have some potential hazards including limited flammability after vaporization into a gaseous state, freezing and asphyxia. More about risks is cited below.

How is it liquefied? The liquefaction process involves removal of certain components, such as dust, helium, water and heavy hydrocarbons. The processed gas is then converted to a liquid by cooling it to approximately -162 °C (-260 °F). The nominal pressure in a special thermos tank configuration is at around 25 kPa (4 psi).

What are the basic rail transport economics of LNG?

The process of compressing LNG to such a degree makes it economical to move huge volumes of the LNG from production wells and/or cryogenic large ground storage tanks to remote areas of the world by rail. It lowers the consumers’ price paid for energy. It can be stored at destination and used to generate electricity or heat by local utilities.

Ocean transportation of LNG has been going on for a considerable time with very few reported safety issues.

By using rail, LNG can be transported to otherwise energy-deficient regions relatively quickly using existing railway track structure.

Safety is still an unresolved public issue. And, yes, it should be addressed.

While awaiting additional safety studies, here are two market examples of how railway movement of LNG is proceeding on a commercial basis.

In Europe, German-based VTG Aktiengesellschaft signed a contract in 2015 with Norway-based Skangass AS to haul LNG by rail. The operation involves leasing up to 20 LNG tank cars that can move as much as ~1,500 cubic meters of LNG per trip. That would replace the use of over the highway tank trucks.

The other LNG European disruptor is Czech Republic-based Chart Ferox, a division of Chart Industries.

Translation – European railway regulatory agencies now have three or more years of actual operational performance with which to determine the railway safety aspects of transporting LNG.

The second disruptive commercial example comes from the Florida East Coast Railroad, or FEC. Operating freight trains over more than 300 miles of track between Jacksonville and Miami, FEC introduced LNG-fueled locomotives in 2017. FEC is now owned as part of the Grupo Mexico Transportes company

Chart designed and built the LNG locomotive fuel “tender” car that is used by FEC. That tanker feeds a locomotive at each tender car end. An investigation of the car design should be useful in examining the operational use risks from the point of view of several different types of side impact and derailment scenarios.

(Photo credit: Florida East Coast Railroad)

In this design, the ISO container holds up to 10,000 gallons of LNG and can dispense natural gas to the locomotives via a submerged pump, via pressure transfer or via an economizer system.

Translation – there are now about two years of daily use operational data and safety incident records involving more than 20 LNG tank car-supplied fuel locomotives from FEC.

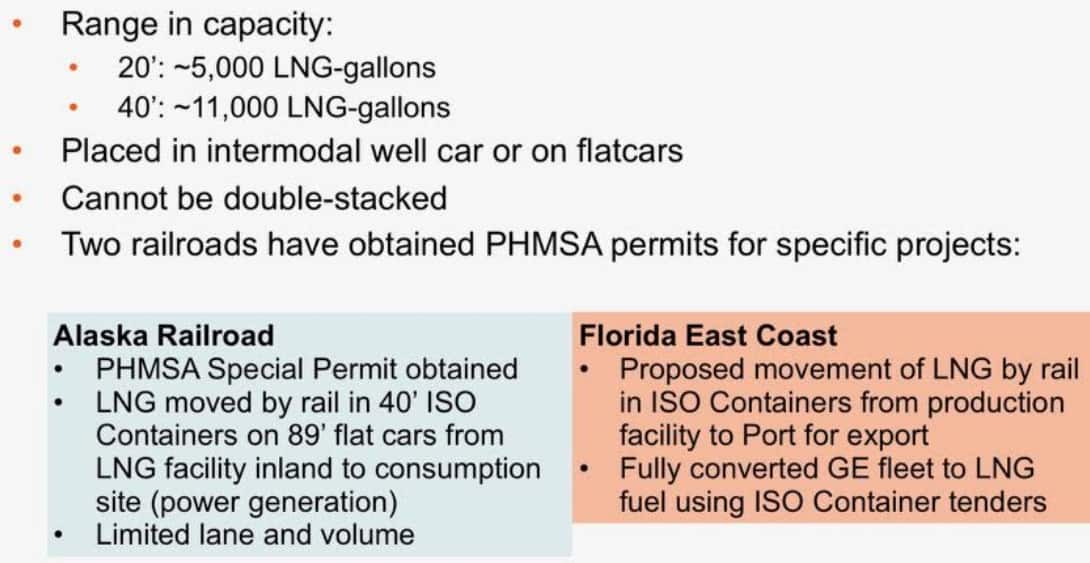

More than a year ago, FEC was exploring opportunities for moving LNG as a commodity, according to the trade publication Railway Age. That included moving smaller lots of LNG in ISO LNG containers on flat cars along a short rail corridor between Hialeah to the Port of Miami and Port Everglades. An ISO tanker is much smaller in cubic capacity than is a full-size railway tank car.

ISO tankers have been used for a long time on ships and intermodal trains elsewhere around the world.

Going forward, an examination of the fundamental LNG safety issue should review the risks associated with moving cryogenically cooled LNG against the risks of moving alternate hazardous materials and fuel including:

- Liquid petroleum gas

- Diesel fuel

- Compressed natural gas

- Gasoline

- Crude oil

- A variety of rail- and truck-hauled chemicals

Conclusions

Public safety, commercial economic benefits and conversion substitution evidence is out there already. Taking multiple years to examine the issue would be embarrassing. What appears to be lacking is a passion for a rigorous yet expedient examination of facts already in evidence.

The Federal Railroad Administration, or FRA, has already been collecting some safety data from both the Alaska Railroad and the FEC projects.

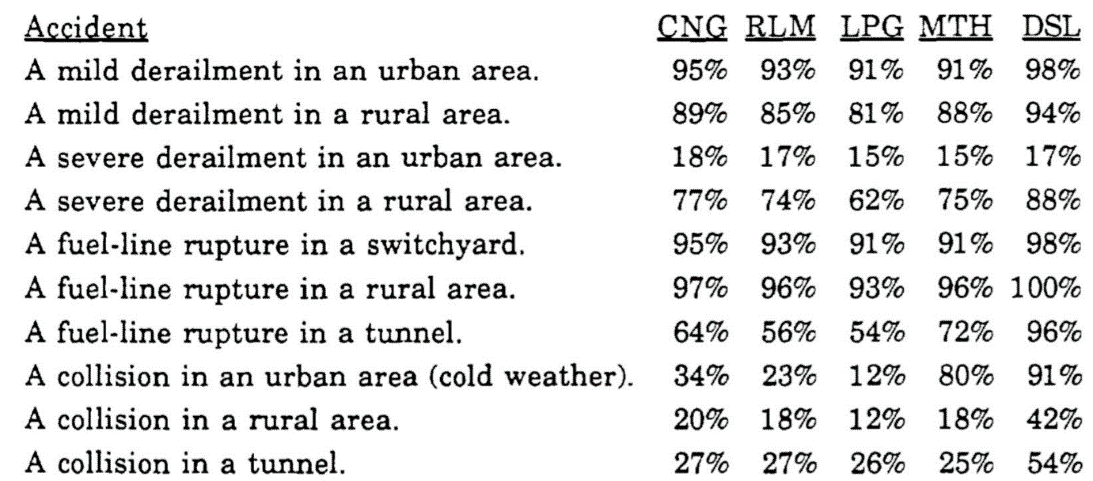

Beyond current monitoring, FRA can use the results of the Burlington Northern Railroad’s (now BNSF) extensive 1982 to 1987 natural gas research. Done by scientists at Los Alamos National Laboratory, those documents were donated by Burlington Northern in September 1990 to the federal government. Those documents can be obtained from the National Technical Information Service of the U.S. Department of Commerce. The Los Alamos tests included compressed natural gas (CNG), refrigerated liquid methane (RLM), diesel fuel (DSL), liquid petroleum gas (LPG) and methane (MTH) as part of five fuel sources against about 10 different types of possible railway accidents. Let’s put that research to use as a baseline assessment.

In Table 1 are the initial Los Alamos safety results identifying the relative safety of five alternative rail locomotive fuels in each of 10 1982-88 tested accident scenarios “equated to the percentage likelihood that no hazard occurs.”

I offer two suggestions in this FreightWaves Rail Market View to get things moving a bit more quickly.

One is to purchase a cryogenic tank car from one or more of the existing vendors (a one-time capital expenditure cost not likely to exceed $2 million), then subject it to both stress and strain forces testing – and then a planned destruction event test at say Pueblo railway test tracks.

The second suggestion is to commission a competitive quote from insurance analysts. After all, insurance companies are in the risk assessment business.

Fear of risks is a logical human reaction to new technology. Yet mankind has the wherewithal to overcome fear with knowledge. Let’s please pick up the pace.

Acknowledgements

These are valuable resources for readers to consult with. My views do not necessarily reflect the specific scientific, safety or business views of these sources.

- LNG and related railway use technical papers by Steve Ditmeyer, railway technical and logistics professor

- LNG by rail tank car work papers by Rich Thoma, Concept Strategy Developer at Red Rhino Disruptive Energy Solutions

- Railway Age editor-in-chief W. Vantuono’s reports on LNG use in Norway, the FEC and other sources – 2013 to 2018

- National Technical Information Service, U.S. Department of Commerce, 1990; “Safety Assessment of Alternative Fuels” by Burlington Northern Railroad

- Joshua Soles, BNSF Market Manager – LNG at October 2019 NEARS rail shipper forum

- “Midway” (Lionsgate) – release date at most theaters is November 8, 2019

Heavy Wreckoning

I didn’t think the delay in LNG by rail had anything to do with safety assessment. I thought it was simply being attacked as potentially dangerous because it is a fossil fuel. If it can be hauled on a highway, it can be hauled by rail. The green energy people are using safety to disguise their agenda of eliminating fossil fuels and the regulatory agencies are playing right into their hands.