Third-party logistics provider GSC Logistics announced Tuesday it would add 100 freight haulers to its network “as global trade booms.”

The Oakland, California-based company said the capacity additions would help expedite diverted cargo from congested ports to its customers in the San Francisco Bay area and the Pacific Northwest. The additions will increase its driver pool by almost 30% at the ports; 250 drivers in Oakland and 100 in Seattle. The new drivers are expected to be on board by summer.

The company also plans to add 15 employees in customer service, dispatch and IT, double freight yard capacity in Oakland to 29 acres, and purchase 400 new chassis.

“We’ve been in business for more than 30 years and the pace of growth is like nothing we’ve ever seen,” said Scott Taylor, GSC Logistics founder and CEO. “We’re taking some pretty dramatic steps to keep ahead of the demand.”

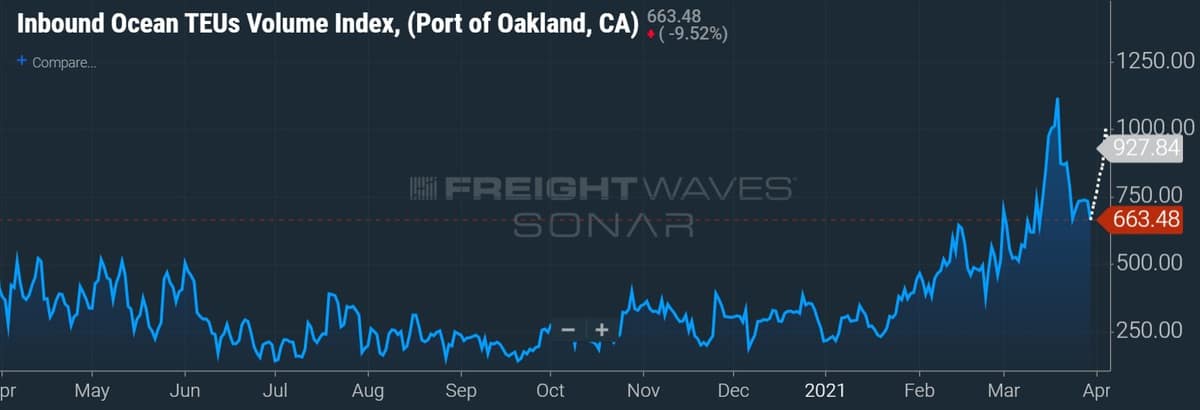

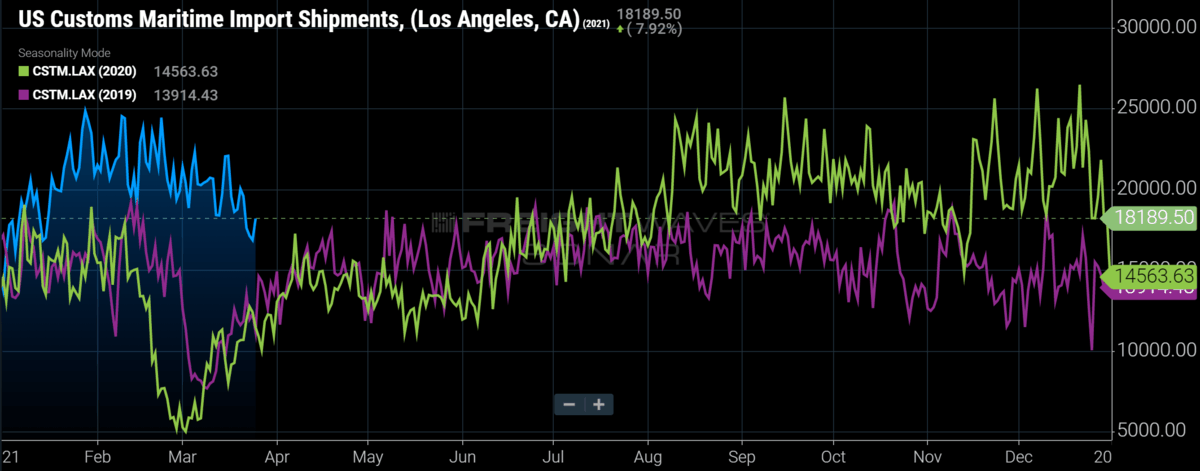

GSC Logistics previously forecast that it would move 25% more containers on behalf of its clients in 2021 due to surging Asia-to-U.S. container traffic and now that the Port of Oakland has been elevated to first-call status. The company expects the “U.S. import frenzy” to last through the second quarter at a minimum.

GSC Logistics primarily moves cargo containers from ports in Seattle, Oakland and Tacoma, Washington. In addition to ocean and intermodal drayage, the 3PL provides refrigerated and dry van truckload services as well as freight brokerage.

The company has created pull-off programs with marine terminals and select importers to isolate freight for cargo owners as it is being discharged. Its drivers are able to swoop in and drive off with the container on an expedited basis. The containers are then stored at one of its yards until delivery requests are submitted.

“This allows GSC customers to shape just-in-time delivery programs,” said Dave Arsenault, president of GSC Logistics. “It provides increased flexibility and efficiency in cargo flow while providing lower cost alternatives that help mitigate the increased costs that have been created by these extreme supply chain disruptions.”