Hello, and welcome to the coolest community in freight! Here you’ll find the latest information on warehouse news, tech developments and all things reefer madness-related. I’m your controller of the thermostat, Mary O’Connell. Thanks for having me!

All thawed out

Maersk’s newly released report, “Trust and Technology: The links in a sustainable cold chain” breaks down the current state of cold chain logistics, establishing a comprehensive end-to-end cold chain operations and maintaining product integrity through tech-enabled necessities.

For now though, we’re focusing on the state of cold chain logistics. Cold chain logistics is anticipated to reach $600 billion by 2026. Cold chain has not escaped its share of challenges. Inflation has caused rates and manufacturing costs to increase, putting upward pressure on everything else, like a domino effect. An issue with a huge impact on the cold chain is energy prices. From running warehouses to trailers, costs of fuel and energy remain at the forefront.

High costs mixed with a lackluster labor market doesn’t make for ideal conditions for the future of cold chain. Consumer demand for fruits and vegetables is expected to grow, putting additional stress on the entire network. The good news, that the Maersk report discovered, is that despite rising costs, consumers are willing to pay, especially if the goods are from an “ethical” brand. Seven in 10 consumers would pay more for products made by producers that pay fairly, operate locally and emit less carbon. Companies able to prove that and incorporate those highlights in their market stand to be in a much better position.

Temperature checks

A new temperature-controlled solution is coming to the middle-mile space. Warp has announced DirectFresh, a service that gives shippers of perishable same-day or next-day store delivery. This allows shippers to move product from cold storage directly to a store or a Warp cross dock without having to work with a last-mile delivery service. Warp is able to provide this service through its partnership with ShipRec, a real-time temperature monitoring service. The technology provides shippers of perishables a one-stop shop for all their logistics needs. This integrated approach helps mitigate risks associated with perishable shipments and ensures that products are delivered on time and in good condition.

Perishable goods are extremely fragile, and their quality can deteriorate quickly. A missed delivery window can lead to a complete shipment of spoiled products, which can result in significant financial losses for the customer. Therefore, it is essential for shippers to have complete visibility and transparency throughout the supply chain, from the manufacturer to the store.

Jake McPaul, head of refrigerated operations and product at Warp, said, “The sensitivities associated with perishable shipping also almost always leave perishable shippers little to no consolidation solutions, making it challenging to manage costs.”

Food and drugs

Impossible is not a word that Impossible Foods knows. The popular plant-based meat substitute company has developed a leaner substitute for the leanest of ground beef. Impossible Beef Lite has 75% less saturated fat and 45% less total fat than the 90/10 lean beef from cows. The new product also is a good source of fiber, iron, B vitamins, zinc and potassium, with 33% less sodium than the competition’s plant-based product, according to the company.

The news release on the new product says, “The new plant-based beef offering complements the company’s existing Impossible Beef product, which is the #1 best-selling retail product across the entire U.S. plant-based meat category in both dollar sales and volume, and is the best-selling product by volume of any plant-based meat brand in U.S. food service.”

Cold chain lanes

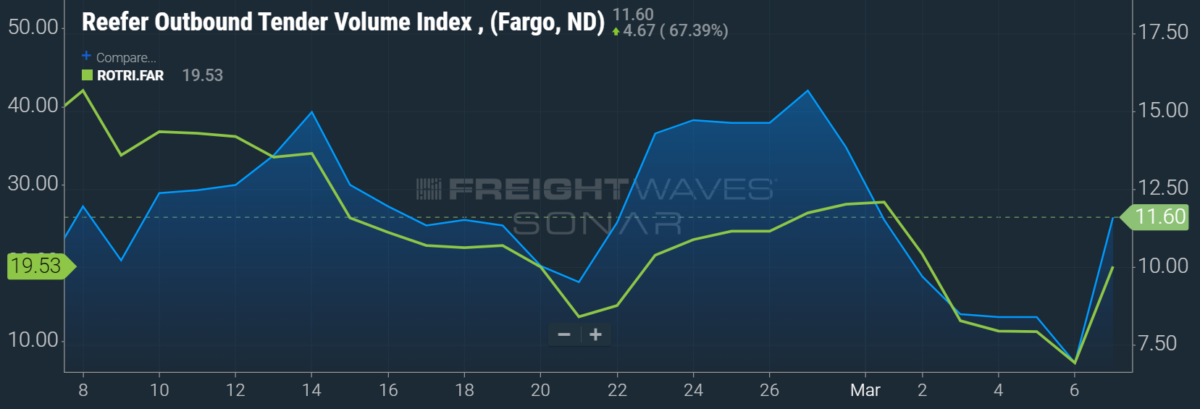

In an effort to protect their temperature-sensitive goods from freezing, shippers in Minnesota and North Dakota are increasingly switching modes from dry vans to reefers. As well as keeping freight cool, reefers can insulate shipments against severe winter weather. Accordingly, reefer volumes rose 45.5% on a week-over-week (w/w) basis in the market of Fargo, North Dakota — one that also covers much of Minnesota’s upper half as well as its border with Canada. Reefer rejection rates in Fargo responded with a sharp rise of 1,440 basis points w/w, with its local Outbound Tender Reject Index (OTRI) now among the highest in the nation at 27.5%.

Is SONAR for you? Check it out with a demo!

Shelf life

Smithfield Foods to close Vernon, CA facility; reduce hog production out West

Americans planning frugal uses for their 2023 tax refunds

What will power ocean vessels under IMO 2050?

Imports sink again as wholesale inventories remain bloated

OK with the change in management? Shoot me an email with comments, questions or story ideas at moconnell@freightwaves.com.

See you on the internet.

Mary

If this newsletter was forwarded to you, you must be pretty chill. Join the coolest community in freight and subscribe for more at freightwaves.com/subscribe.