Aurora Innovation is the latest autonomous trucking developer to announce longer routes than hub-to-hub operations in Texas. It helps make the real-world case for long-promised over-the-road driverless trucking that could dramatically reduce the cost of freight shipping.

Aurora said this week it will begin driver-supervised routes from Fort Worth and El Paso, Texas, to Phoenix next year. It plans to go driverless by the end of 2025.

‘Real benefits of AV start to be unlocked’

“This is where you see the real benefits of AV start to be unlocked,” Zac Andreoni, Aurora vice president of business development, told me. “You may even see freight move from different modalities. We’re excited to see and test all that stuff.”

Conservatively, driver compensation including benefits accounts for 40% of the operating cost of a truck. While the per-mile fee to run autonomously is significant, it is far less than the cost of a human versus robot driver.

“You get to pull out some of that driver cost and not have to deal with some of the traditional constraints of being a carrier,” Andreoni said. “You can run this truck back and forth on that lane, presumably significantly more than you could if you have a single asset and a solo driver.”

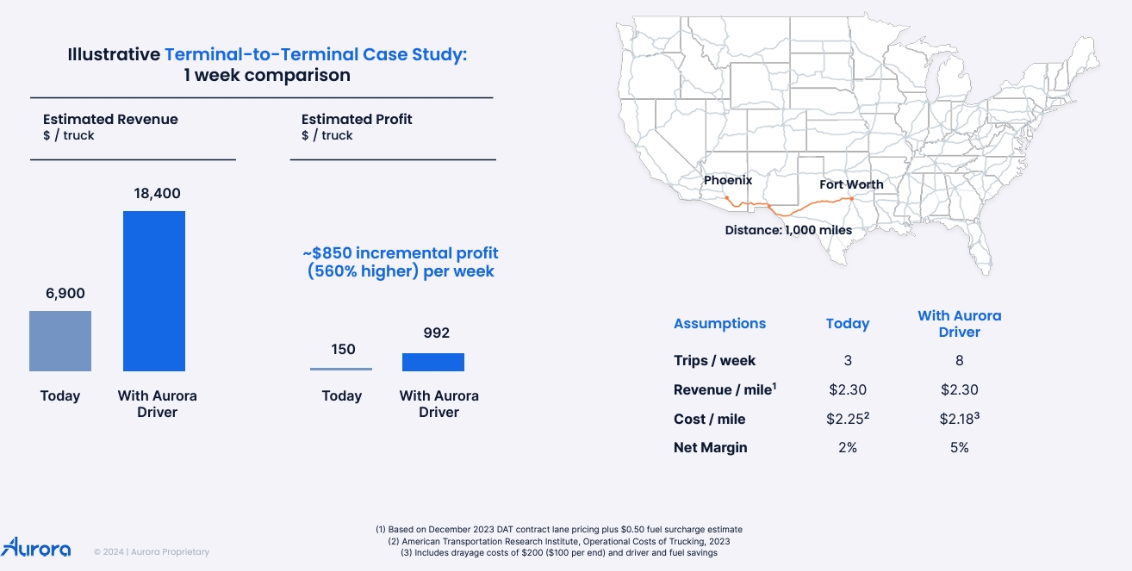

Aurora CFO David Maday told analysts in March that driverless operation could enable a “nearly 600% increase” in profit per truck per week on the Phoenix-to-Fort Worth lane because it can deliver more loads at a lower cost.

Shortening time between monitored and driverless trucking

Aurora needed about three years to close its safety case for runs on I-45 between Houston and Palmer, Texas. With that work all but complete, Aurora plans to pull the driver from up to 20 autonomous trucks by the end of this year.

That timing could slip by a few months. But it would not impact Aurora’s business case, Canaccord Genuity analyst George Gianarikas said in an investor note on Monday.

“We’ve taken a really focused approach on our launch lane and how we pilot today, and when we hit our commercial launch, it will have taken several years,” Andreoni said. “Because of the artificial intelligence engines we use to accelerate development and validation, the speed should compress considerably” on the Fort Worth-Phoenix route.

Aurora plans to launch that route with safety drivers in mid-2025. It plans to operate without human drivers by the end of next year.

“If you close a safety case on Dallas to Houston, you can imagine that there aren’t a truly significant amount of new additional things you’ll be testing for on a leg that goes from El Paso to Phoenix,” Andreoni said. “And so each lane we open after that is presumably faster and faster.”

Not alone on longer hauls

Rivals Kodiak and Torc each operate a long-haul route. Kodiak is conducting five to six runs a week from Houston to greater Atlanta, about 780 miles on I-10 East. Kodiak hauls loads for J.B. Hunt and Werner Enterprises using a specially equipped Pilot truck stop in Villa Rica, Georgia.

Torc operates a 960-mile, driver-supervised run on I-40 between Oklahoma City and Phoenix for Schneider and C.R. England. The 14-hour trip would require a driving team or a mandated 10-hour break for a single driver.

These longer hauls speak to the value proposition of autonomous trucking, especially for time- and temperature-sensitive loads.

Forterra raises $75M for military and off-road autonomy

Forterra, formerly known as Robotic Research, pulled in $75 million in a Series B funding round.

The Clarksburg, Maryland-based company recently expanded into distribution yard autonomy and has a strategic partnership with yard tractor maker Kalmar.

Forterra previously focused on developing off-road autonomous applications for the U.S. military, an area of continued focus. It operated for 20 years on proceeds from military contracts before raising $228 million in a Series A round in December 2021.

(Photo: Forterra)

“Forterra has proven that self-driving technology can be deployed today to solve real-world challenges in demanding environments,” Josh Araujo, Forterra CEO, said in a news release Tuesday. “This funding allows us to further develop, test, and deploy self-driving platforms with ever-increasing capabilities for both defense and industrial applications.”

Distribution yard autonomy adding new players

Forterra’s early work in human-monitored autonomous tractors joins efforts by several other companies. They see the importance of cleaning up the environment around dirty and dangerous yards where drayage trucks move in and out around the clock.

Brighton, Colorado-based Outrider, which raised $73 million in a Series C round in 2023, leads in the distribution yard space. It has automated multiple functions, including attaching and releasing trailer brake cables as well as tracking trailer movement.

Mitsubishi Electric Automotive America in August announced the HubPilot autonomous distribution yard logistics platform as a service.

HubPilot works in geofenced distribution centers and logistics hubs, employing multisensor inputs on autonomous terminal tractors. The sensors, combined with software, allow the platform to visualize the yard trucks’ surroundings, identify assigned trailers and confirm their locations.

Cambridge, Massachusetts-based ISEE and Germany-based Fernride also are pursuing distribution yard automation. Fernride raised $50 million in a Series A round in 2023.

Military contracts boosting Hyliion’s generator prospects

Hyliion Holdings is getting additional interest in its fuel-agnostic electric generator technology from the U.S. Navy.

The Office of Naval Research (ONR) is paying Hyliion $15 million to build and demonstrate a 250-kilowatt Karno generator module. Then it wants Hyliion to take it apart and evaluate it. The goal is to find out if Karno could become a power source for future naval platforms.

“This new partnership with the ONR is a testament to the performance and potential of our Karno generator technology,” Hyliion CEO Thomas Healy said in a news release Monday.

In August, the Navy awarded Hyliion a Small Business Innovation Research government contract to create a preliminary design of a megawatt Karno system. It wants to see if Karno can meet the U.S. government’s Unmanned Surface Vessel cross-platform requirements.

Hyliion last year abandoned plans for a natural gas-powered and electric hybrid Class 8 truck. It was known as the Hypertruck ERX. Cost overruns and lack of customer commitments led to its demise. The company laid off 175 employees – about two-thirds of its workforce – in the process.

Hyliion acquired the Karno technology from GE in 2022 for $35 million. It is focused on additive manufacturing, also known as 3D printing, to make stationary generators its main business.

Briefly noted …

Nikola founder Trevor Milton lost his appeal of a $167.7 million arbitration case and must pay the electric truck maker, Reuters reported.

Construction is underway on the Greenlane joint venture’s first public medium- and heavy-duty electric truck charging hub with 60 high-powered chargers in Colton, California.

Separately, Zeem Solutions is breaking ground Monday on its Long Beach, California, site, which is expected to be the largest commercial charging depot in the U.S., capable of charging up to 500 vehicles per day.

Mack Trucks is upping its visualization game with a new configurator that features full 3D renderings of Mack exteriors and interiors across the lineup.

Volvo Group Venture Capital is among investors in a $16.6 million Series B fundraising round by Aifleet, which is trying to drive efficiency in the fragmented truckload segment.

Truck Tech Episode No. 82: Applied Intuition provides backbone and software tools to advance automation

This time we mean it. Nominations for the FreightTech 25 really do close at 6 p.m. EDT. Winners will be announced at the Future of Freight Festival in Chattanooga, Tennessee, in November.

That’s it for this week. Thanks for reading and watching. Click here to subscribe and get Truck Tech delivered to your email on Fridays. And catch the latest episodes of the Truck Tech podcast and video shorts on the FreightWaves YouTube channel. Send your feedback on Truck Tech to Alan Adler at aadler@firecrown.com.