The transportation industry is plagued with waste. In fact, nearly half of the heavy-duty trucks on the road at any given time are carrying less than half the inventory they were designed to hold. This means that about 25% of available truck space is wasted on a day-to-day basis.

This year has been financially precarious for the transportation industry, and these high percentages of wasted space contribute to ongoing economic headwinds for shippers and carriers alike. When a truck is running half empty, shippers end up paying for unused space and carriers miss out on opportunities to make more money.

Flock Freight is passionate about cutting out that waste through its industry-leading shared truckload solution, FlockDirect.

“Flock envisions a world without traditional shipping constraints, where customers can produce and ship goods as needed,” Flock Freight founder and CEO Oren Zaslansky said. “At the same time, carriers increase their earnings through optimized trailer space utilization.”

FlockDirect uses real-time data to pool freight for multiple customers. The solution effectively dismantles the physical hub-and-spoke constraints that have defined the supply chain for more than a century. In its place, Flock created a modern, digital platform that puts customers first.

Most recently, Flock implemented a strategic initiative aimed at integrating AI into all facets of its core technology, fusing machine learning with operations research.

“While Flock’s underlying technology is complicated, the concept is simple: We keep trucks full by bringing together multiple shippers whose goods are heading in the same direction,” Zaslansky said.

As a result of those efforts, hundreds of millions of pounds of freight have been pooled to date. That number is expected to grow significantly in the near term due to shippers wanting better, more cost-effective ways to ship their freight, leading to serious financial gains for industry players and environmental gains for the planet.

“More pooled freight equals a smaller carbon footprint in the logistics and transportation industries, something that has never been done before,” Zaslansky said.

Real example of a recent pool

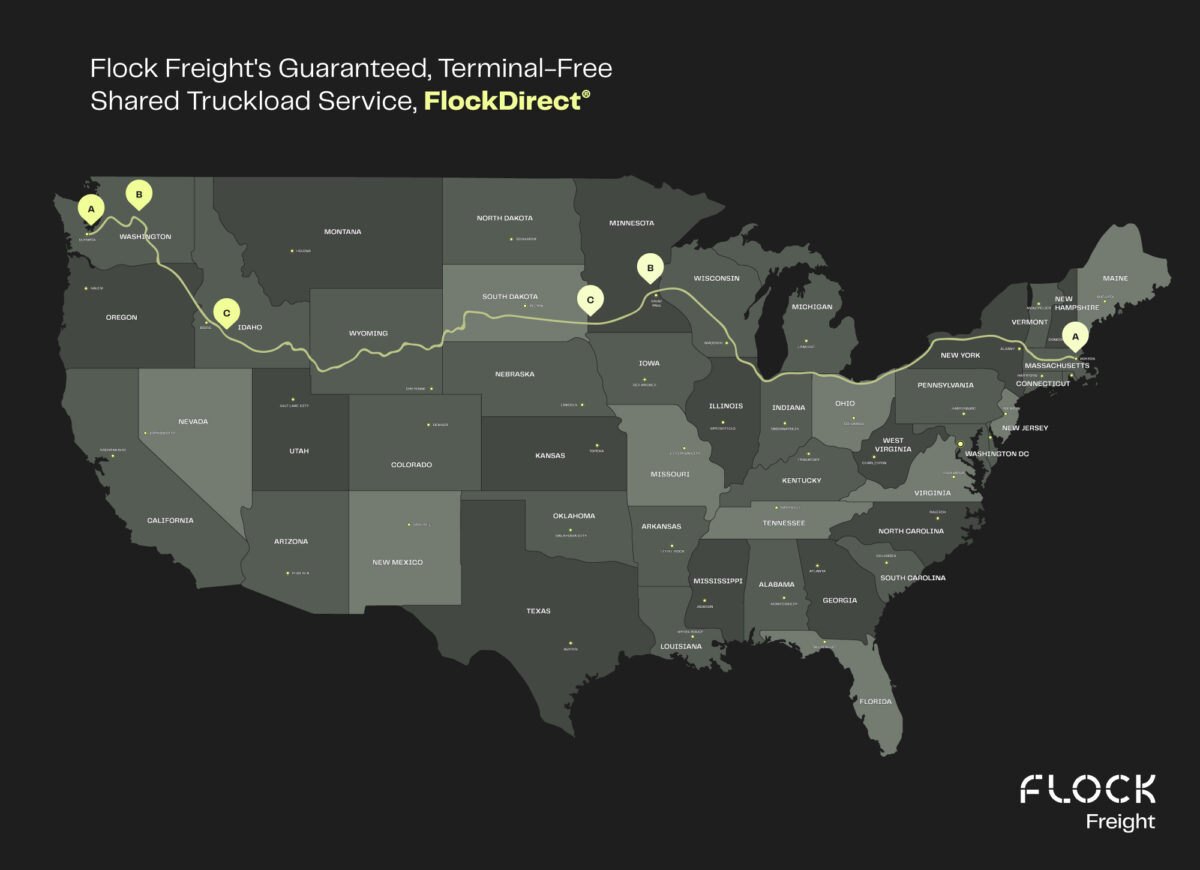

Flock recently executed an extensive pool that spanned from the Pacific Northwest all the way to Massachusetts. To pull this off, the carrier embarked on a 3,523-mile journey hauling a trailer loaded with a diverse range of household goods from three pooling customers.

Originally, the carrier had booked only two pickups in Washington, headed for Minnesota and Massachusetts. Those pickups, however, only filled 54% of the trailer. During transit, Flock managed to pool more freight by adding another pickup and drop-off between the initial stops, boosting trailer utilization to 86%.

This created a win-win-win scenario:

- Shippers found unmatched value using shared truckload: By pooling shipments together and only paying for the space needed, shippers were able to significantly reduce costs while experiencing the highest quality service — all with the added value of a reduced carbon footprint compared with other traditional modes.

- The carrier earned more revenue: By strategically adding another pickup and drop-off between the initial stops, Flock managed to fill the carrier’s trailer by an additional 32%. This increased efficiency resulted in the carrier earning more money by transporting even more goods than anticipated in a single trip.

- The environment benefited from reduced carbon emissions: By combining multiple customers’ shipments into a single trailer along a single, efficient route, the number of cross-country trips needed to deliver these goods was ultimately reduced. This in turn reduced fuel consumption, and consequently, avoided unnecessary carbon emissions.

These pooling opportunities will become more common as shippers and carriers continue to choose shared truckload as their primary method to move goods.