Local union freight workers were among those New Jersey-based Staxxon approached for initial feedback on its shipping containers that fold and bundle for space-saving storage.

After examining the containers, the workers offered an unexpected response.

“They said all of our open profiles … needed to be sealed off so people couldn’t put drugs inside them and smuggle them in,” George Kochanowski, founder and CEO of Staxxon, told FreightWaves.

The safety beams and the headers and sills that frame the front and rear of Staxxon’s containers had consisted of hollow steel tubes. Based on insights from those union members, the company created subsequent prototypes that replaced the tubes with solid steel beams, and the safety beams were sealed at both ends.

“Drug smuggling is no longer a concern,” Richard Danderline, CFO at Staxxon, told FreightWaves.

Of greater importance, folding empty containers could reduce the possibility of smuggling weapons or trafficking humans in containers that are declared “empty” as they go through U.S. customs, Danderline said.

“In the case of Staxxon bundled sets, those possibilities are greatly reduced, if not eliminated,” he added.

Thanks in large part to the union guys from Jersey. The evaluation process will accelerate later this year when Staxxon conducts field trials of its containers, in which up to five empties can fold into the space of one.

Staxxon has made nine prototypes, each with incremental improvements that led to a design certified by the Convention for Safe Containers. Field trials should help the company gain confidence in the existing design or make further improvements as Staxxon begins commercial manufacturing this year.

Trials should also provide the company with accurate emissions-saving data associated with transporting different-sized bundles of folding containers.

“We want to put the boxes — specifically the bundled sets of empties — through their paces in ‘real-world’ conditions, using all the existing container handling equipment already in use at the ports to see how they perform,” Danderline said.

Why folding containers?

Empty shipping containers are increasingly being shipped overseas and taking up space at ports and distribution centers. Transporting empty containers where they need to be takes time, fuel and money.

Several designs for containers that collapse vertically have come to the shipping market to save space on vessels and trucks, but they haven’t taken off. Why? They often can’t be stacked atop each other in their collapsed state. That requires that they be shipped as “special” containers, which costs more.

Kochanowski believes his company has found the solution. Staxxon was named partly because its folding containers can “stack on” each other just like a conventional shipping container.

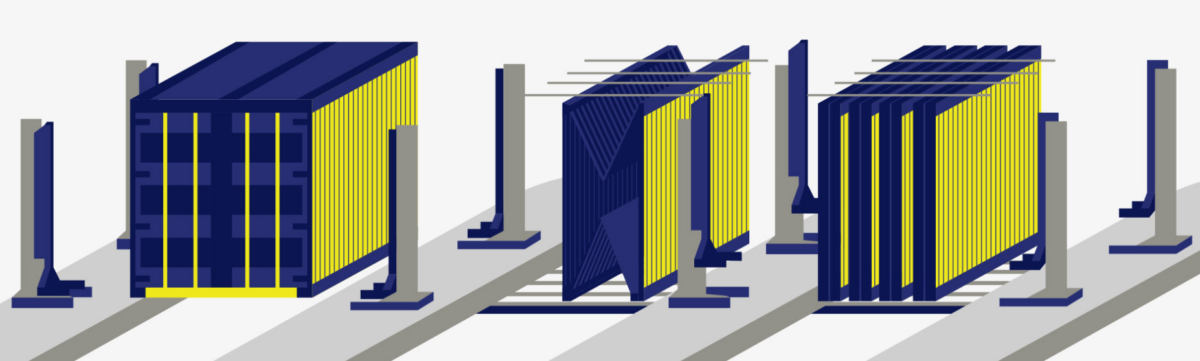

Yet Staxxon’s containers also fold accordion-style and can be shipped with two to five empty containers in the space of one International Organization for Standardization (ISO) container.

Right now, Staxxon estimates that fewer truck movements and fewer lift movements at ports could theoretically eliminate 63 million metric tons of carbon emissions annually by bundling five empty containers into the space of one, based on company calculations available on the website.

Similar calculations estimate 200 million metric tons of emissions from ocean vessels could be avoided annually, Chief Strategy Officer Santtu Seppala told FreightWaves. That’s the greenhouse gas emissions equivalent of taking more than 43 million passenger vehicles off the road for a year.

Staxxon hopes to get its folding containers on the market for purchase by the end of 2023, Seppala said.

“I’d like to do it faster,” Kochanowski added.

Read: Report: Climate change could cost shipping industry $25B annually by 2100

The folding and unfolding process

Staxxon’s containers can be transported with two to five empty containers in the space of one ISO container.

“The critical issue when it comes to folding and bundling and unfolding and unbundling is that what our technology is designed to do in its essence is to relieve congestion and relieve bottlenecks as it relates to the transport of empty containers,” Danderline said.

“So the most critical thing for us is to make sure that those processes … do not in themselves create other bottlenecks because then we would be diluting the advantage of using folding containers.”

Staxxon is working with Konecranes on a design for a high-speed, high-volume folding and nesting machine. The goal is to be able to fold a container within three minutes and get a set of five containers folded and bundled together in less than 15 minutes.

In places without access to a folding machine, Danderline said that containers could be folded and unfolded using a forklift and a couple of crew members. At ports or distribution centers with little equipment, it could even be done with ratchet straps and more crew members. But the less equipment available, the longer the process would take.

Ports are already congested enough, so Seppala predicted that the best place for folding and unfolding is an inland distribution center rather than at terminals.

Added Danderline: “There just isn’t enough room, especially right now, at any of the ports, and most of the ports have no ability at this point to expand any farther.”

Paying fewer gate fees and using fewer trucks to transport containers into or out of ports are among the benefits of using folding containers. If the containers were folded and unfolded at ports instead of inland distribution centers, some of those economic and environmental benefits would be lost.

Read: One solution to the congestion problem: More inland ports

“I’m hopeful that a solution like Staxxon’s folding containers is adopted by the market. Efficiency gains should always be prioritized in decarbonization efforts. Giving operators the ability to stack multiple empty containers without losing flexibility in vessel configurations would be a huge gain in operational savings and reduced empty moves,” said Tyler Cole, director of carbon intelligence at FreightWaves.

Why not just more ISO containers?

Recent supply chain and port congestion issues have made it more apparent that “having more containers does you no good if those empties are not where they need to be when they need to be there,” Danderline said.

Being able to ship two to five containers in the space of one could speed the process of getting empty containers to their destinations.

Staxxon’s containers also have a self-weighing mechanism. The way the patented floors fold allows the container to weigh its contents using sensors in the floor — a feature that isn’t possible with a standard container, Danderline said.

The Safety of Life at Sea treaty requires shippers to provide the gross mass of each container prior to bringing it to the pier for shipping to avoid collapses. Accurately weighing containers is important for creating safe container stowage plans on vessels. But there is a cost for weighing containers, and Staxxon’s container owners would not incur that expense.

Read: Some call it a shipping container, others call it home

How much will they cost?

Once the company achieves high-volume manufacturing, Seppala said he expects the cost to be 1.5 to 1.6 times higher than that of a conventional container.

“Our containers will always be more expensive, but the cost savings from the operations side of using them more than makes up for the initial higher cost,” he said.

Standard containers are only an expense. Danderline said the investment in Staxxon containers would be paid back in a matter of months by the savings of shipping empty containers folded to take up less space.

The payback period would be especially short right now due to the high volume of containers being shipped overseas empty.

Modular benefits

Most shipping containers are essentially steel boxes welded together. If a door, floor or roof needs to be replaced or repaired, it could be out of service for days. Staxxon’s containers are modular and held together by bolts and screws instead of by welding metal.

“Our container is tougher, and because it’s modular, we’ve made it more manufacturable,” Kochanowski said.

The doors, floors, roofs, headers and hinges can be manufactured separately and brought together for construction. The modularity makes it easier to replace or repair parts.

Where a standard container may be out of service for days with a faulty door, Staxxon’s container doors can be replaced in about 20 minutes with two crew members, Kochanowski said.

Read: Want your own farm? This one comes in a shipping container

Are folding containers the same as collapsible containers?

“When we first started this endeavor, we had a lot of doors immediately slammed in our face” because many shippers had already had bad experiences with attempts at using collapsible containers, Danderline said.

Staxxon representatives said it has been a challenge to get people to understand that these fold vertically, whereas most collapsible containers fold horizontally. Collapsible containers, therefore, require cranes or other heavy equipment to lift the roof up and expand a collapsed container into its full shape.

Staxxon containers are always the same height and take less equipment to fold and unfold.

Collapsible containers are somewhat like a stack of books, Danderline said. They move around as they are transported, so they can’t be stacked very high, which takes away some of the economic benefits. Staxxon’s containers are stackable to the same degree as conventional containers.

If a collapsible container design could fit five containers into the space of one, companies would have to wait until they had five containers to ship together or ship them as special units, which is more expensive.

Staxxon containers can be shipped with any number between two and five containers folded into the space of one. And they always have the dimensions of a standard ISO container.

The mechanisms that allow a container to collapse down take up space inside the container, meaning it can’t hold as much as a standard container. This makes it more difficult to fill collapsible containers because their heights inside are not standard. Staxxon’s folding containers have standard dimensions inside and out.

Port congestion, supply chain disruptions and growing sustainability targets have helped Staxxon get its foot in the door with more shippers.

Now, it’s a question of how fast Staxxon can get its folding containers to market, how much shippers will pay for them, and how smoothly the folding and unfolding process will go in real-life situations.

Click here for more FreightWaves articles by Alyssa Sporrer.

Related Stories:

What if we just folded all the shipping containers?

Amply Power unveils shipping containers for cheaper, portable EV charging

Just how extreme is China’s lead in the container port business?

Ports of LA, Long Beach clear containers, set January records