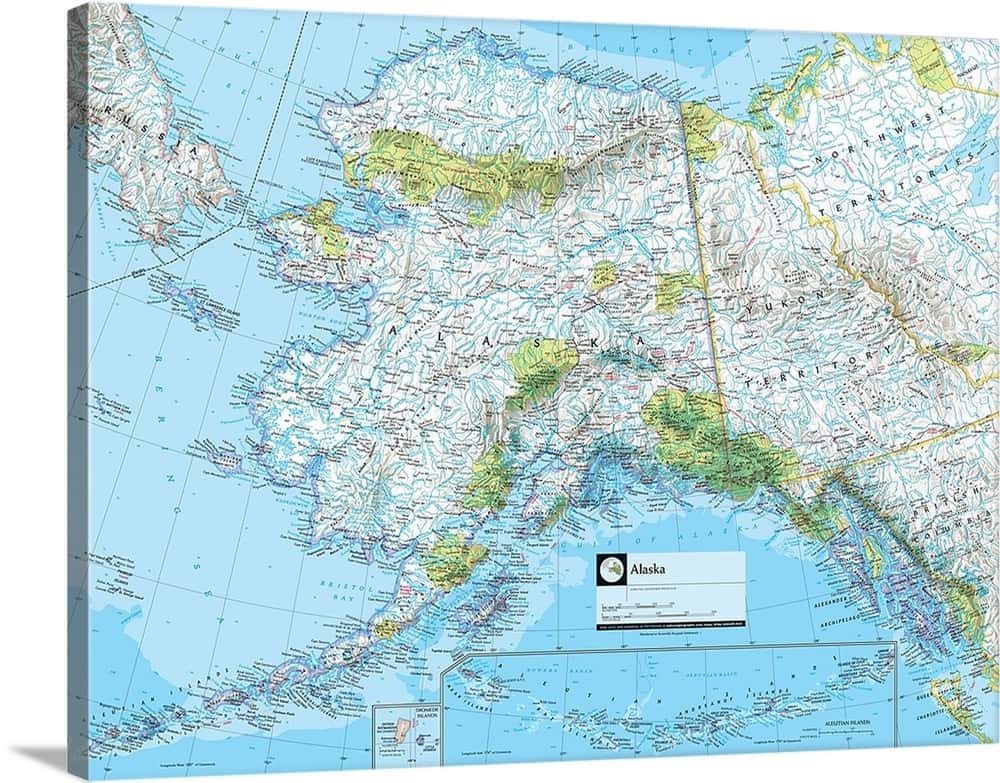

Logistics in Alaska can be both amazing and frustrating. Alaska is the most expansive and diverse logistics laboratory in the United States. Take the largest state in the nation, yet the third least-populated, spread the people throughout the state, support them with only basic infrastructure having little to no redundancies, separate them from the rest of civilization by the vast Northern Pacific Ocean and the expanses of the Yukon Wilderness, and toss in the prevalence of bitter winter cold, earthquakes and volcanoes. Considering all this, one is amazed at the creature comforts Alaskans have access to and have grown used to.

What is frustrating is to consider the challenge Alaska faces in keeping its fragile logistical web from fraying and breaking. Currently, the Port of Alaska is the most fragile strand within that delicate web. If the port became inaccessible most Alaskans would run out of food and other consumer items within a couple of weeks unless an alternative port could be utilized. Most of these items are delivered by four container vessels making weekly voyages from the Port of Tacoma, Washington. Two arrive on Sundays and the other two on Tuesdays. But when one of these vessels is late by even a day or two grocery store shelves will have gaping holes in some places.

It is true to say that Alaska’s economy survives or thrives on how its supply chains are structured and how they facilitate transportation to and from the state. It is also true to say that the Port of Alaska is in real trouble; and all of Alaska’s transportation professionals know it. Even the elected officials and bureaucrats of the municipal government in Anchorage (which owns the port) and those in state government in Juneau know it. They have all known it for more than a decade. Yet the professionals and the political powers-that-be are not able to come together as a group and figure out exactly what to do in the medium-to-long term. In the short-term all that can be done are quick fixes that only buy time.

But time is not on the port’s side. The docks were built in 1961 and their supporting metal piles are rusting rapidly. The most severely challenged piles have been retrofitted with steel jackets; but that only slows down the corrosion of the pile somewhat. If an earthquake of sufficient magnitude and epicenter were to hit, the dock would likely fall into the waters of Cook Inlet. It was pure luck that saved the port on November 30, 2018 when a magnitude 7 earthquake hit where it did (i.e., about 10 miles north of the port). In short, the only solution is to build a new, more resilient port. But this requires a mixture of political resolve informed by logistical realities.

Consider the logistics first. The Port of Alaska (originally called the Port of Anchorage) came to prominence after the magnitude 9.2 earthquake in 1964. That quake destroyed the state’s gateway, the Port of Seward. The Port of Alaska, about 75 miles away from the epicenter, was left intact. The logistical center of gravity shifted north from Seward to Anchorage. Incidentally, it was not the shaking that destroyed the Port of Seward, it was the resulting tsunami waves. Happily, the Port of Alaska’s locale along Cook Inlet’s shallower and narrowing waters make it tsunami-proof. Not so happily, however, those waters have the second highest tides in North America; are fed by silty glacial run-off; and are burdened by numerous winter ice floes. This is the main reason why the dock piles are rusting away so quickly and persistently. The Port of Alaska, for its size, may be the most dredged port in the world, including the need to dredge during icy winter months.

With about half of Alaska’s widely dispersed population centered in Anchorage and Fairbanks, the Port of Alaska has become the only reliable gateway for large volume freight deliveries to those cities. About 90% of Alaska’s inbound freight arrives by water. The Port of Alaska’s share of this serves about 85% of Alaskans. Importantly, of the amount that arrives in Anchorage, only half is for local residents. The other half is for residents outside of the city northward along the highway and railroad up to Fairbanks.

The closest viable port is in Whittier but, like Seward today, neither has the gantry cranes that are necessary for lift-on, lift off (LO-LO) operations, which are performed by Matson Navigation. Roll-on, roll-off (RO-RO) operations, which are performed by TOTE Maritime, are possible at both of those ports but the process of loading and unloading would go from one day in Anchorage to multiple days. Furthermore, the single highway leading into Anchorage and Fairbanks would be highly congested by trucks when the containers are moved to the population centers. The problem with planning for emergencies if the Port of Alaska were severely impacted is that the other ports might be impacted as well – or the connecting highway might be. In this context one can appreciate the fragility of Alaska’s logistics. Furthermore, in the contiguous U.S., if there is a localized or even statewide emergency, civilization and help are just on the other side of the impact area. Not so in Alaska.

Now consider the political resolve. The bottom line here is that life is not fair. Transportation regulation in the United States is not homogenous across the five basic modes (i.e., air, water, rail, motor carrier and pipeline). Each regulatory set is a creature of its own unique history. For example, Ted Stevens Anchorage international Airport can rely on federal money for runways and other projects because the U.S. airspace and its support infrastructure are considered strategically important. Not so in the maritime sector because federal regulations cover the open waters but end at the shoreline. Thus, port construction and operations are the purview of state and local governments. In Alaska, however, those levels of government are not awash in revenues right now. At the state level Alaska’s revenue flow is 90% dependent on oil company taxation, which in turn is dependent on the volatility of the world price of crude oil. Since that price has fallen from about $100/barrel to around $55/barrel in five years, the state is going through the political struggle of searching for alternative sources of revenue (be it an income tax or a sales tax) or resorting to slash-and-burn program cuts. At the municipal level the problem is that Anchorage’s tax base can only be stretched so far. The current estimate to replace the dock is $1.9 billion. The Anchorage Assembly also knows that the port serves thousands of people outside of their tax jurisdiction and it worries about the perception to their constituents of overburdening them. They look to the state for funding, but the state is fiscally challenged. Nonetheless, the Port of Anchorage became the Port of Alaska in 2017 when the Assembly decided to send a polite signal to Juneau about who really are the port’s users.

The Port of Alaska has three main docking terminals. But even with three there is no redundancy since each is separately tasked for very different operations – RO-RO, LO-LO and refined fuel delivered on tankers or barges. There is also an area at the fuel terminal dedicated to cement storage. Thus, each terminal has its own support infrastructure.

A public-private partnership is an option to raise funds to build a new port. But, apart from there being no private takers at this time, any private partner would want to earn a rate of return on its investment. Naturally, transport to and from Alaska is expensive because of the distance and lack of backhaul opportunities. Alaska has a lot of consumer goods coming in over the water and a lot of crude oil, natural resources, and some recyclables going out. Unfortunately, the vessel configurations used in each direction are different. The backhaul problem in Alaska is a perennial one. No backhaul means that Alaskans foot practically all of the round-trip costs on their own.

Some look to the Federal Emergency Management Agency (FEMA) as one federal agency that could build a new port. The problem is that it would have to be in response to a disaster in which the port collapsed (which we should try to guard against, not just wait for). Even then, FEMA would only build to a level of replacement of pre-existing infrastructure. It would likely be a replacement better than the 1961 vintage dock but not very much better. In the meantime, many Alaskans would face food and fuel shortages for weeks if not months. Building an Alaska port for earthquake resilience would take an amount of time and resources beyond FEMA’s mandate.

Some look to the port’s neighbor, Ted Stevens Anchorage International Airport, to provide an emergency stopgap of air cargo deliveries to replace any inbound water transport. Leave aside the fact that on top of the airport’s normal business of about 100 cargo landings per day, at least a couple of hundred more wide-body aircraft would need to be flown in daily just to replace the normal inbound water transport. Furthermore, if a dock can fall into the water as a result of an earthquake, a nearby airport’s runway could be turned into a strip of cleaved concrete. To make matters worse, most of the aviation fuel the airport uses in its gas-and-go services provided to U.S.-Asia air cargo carriers comes from deliveries to the Port of Alaska’s fuel dock.

Is the Port of Alaska in limbo and simply waiting for disaster to strike? No. It is starting the process of dock replacement on a piecemeal basis. While there seems to be no other choice given the current political realities, this small step does highlight how interconnected and fragile Alaska’s logistical web is. The first step is to replace the refined fuel and cement terminal over a two-year period (at an estimated cost of about $225 million). How will it be financed? The intent is to raise the fuel tariff from 0.38 cents/gallon to perhaps as high as 2.4 cents by 2023 (i.e., a 532% increase over four years). The problem is that those costs will be passed along by the port’s fuel carriers to the airport’s consortium of air cargo carriers. They buy the fuel and have it pumped via pipeline from the port to the airport’s fuel storage tanks. These air cargo carriers make their decisions on whether or not to land at an airport and refuel by looking at every last fraction of penny per gallon. If some of the air cargo carriers in the coming years decide to overfly Anchorage on their U.S.-Asia routes the ripple effects in Alaska will not be small. Such is the delicate, interconnected nature of Alaska’s logistical web.

A supply chain is only as strong as its weakest link. A logistical web is only resilient if it has redundancies built in. These are in short supply in Alaska right now. When the logistics process is working smoothly it is an amazing thing. But the nature of the problem Alaska faces is frustrating because everyone agrees on the problem but cannot figure out a resilient solution to share the burden. Alaska’s logistics laboratory toils on.