Editor’s note: This article is part of an ongoing series that examines key innovations in transportation and teases out lessons that can lead to better innovation in sea freight. The opinions expressed here are those of the author and not of FreightWaves or its affiliates.

The completion of the transcontinental railroad in the United States in May 1869 was truly revolutionary. A cross-country trip that previously required four to six months of substantial effort was reduced to a mere seven days — a 95% reduction in time. The cost reduction was equally dramatic. A trip from New York to San Francisco dropped from more than $1,000 to $70, a 93% reduction. Most importantly, the risk of death from disease, weather or hostilities was almost eliminated. The transportation of goods and people was transformed and the country became a lot smaller.

The book “Nothing Like It In the World: The Men Who Built the Transcontinental Railroad 1863-1869” by Stephen Ambrose tells of the efforts of the Union Pacific Railroad Co. (UP) to build west from Omaha, while the Central Pacific Railroad Co. (CP) built east from Sacramento, California. The goal was to build a single continuous track over 1,775 miles (2,856 kilometers) of undeveloped country in the shortest time possible and connect the West Coast to the rest of the U.S.

A vision of President Abraham Lincoln for east-west connectivity was the catalyst for the project. In 1863, Congress gave the UP and CP the exclusive right and responsibility to build the line. The authorizing legislation funded a system of loans, loan guarantees and land grants to allow both railroad companies to raise the necessary capital to fund necessary materials and workforces exceeding 10,000 laborers each. The U.S. military provided security to the UP against Sioux and Cheyenne attacks. The genius of the program was a competition between the two companies to try to build the most miles in order to earn the most money. The whole effort was truly a public-private partnership.

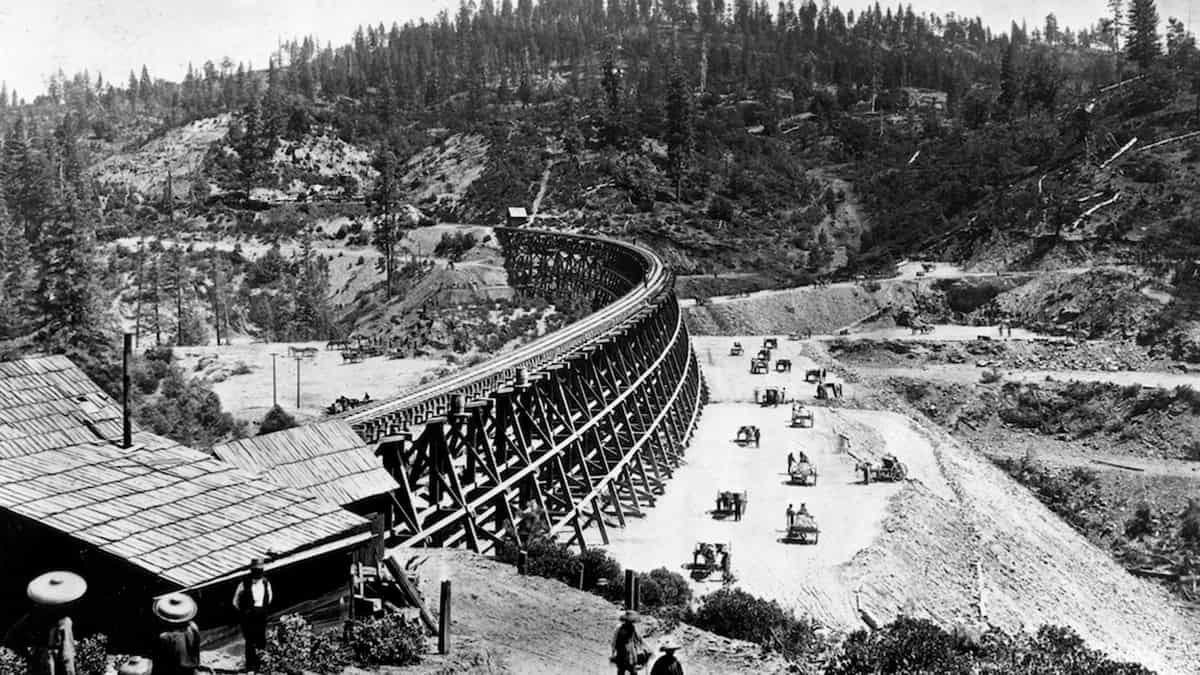

The engineering was incredible. Building a railroad involves creating a flat line for tracks with no more than a 2% grade. The teams had to do this while crossing both the Sierra Nevada mountains and the Rocky Mountains. They had to cross rivers and gorges. They had to tunnel through solid granite when they could not go over a peak. They had to fill low areas and cut high areas so that the line was flat for the tracks. All of this work was done by human effort with animal support. There were no machines to help with the work.

Beyond the construction challenges, the team had to deal with the weather. One winter snow exceeded 60 feet in the mountains where the tracks were being laid. Terrible natural and man-made fires would periodically hinder work. Both companies went through desert areas without easy access to water or food. The logistics of supporting the work teams was made possible only by the recent invention of the telegraph and the completion of the first transcontinental telegraph line in late 1861. This technology allowed a new level of coordination that made possible a project of a scale never before achieved. The entire project was revolutionary in every aspect of the word.

Three lessons for sea freight

1. Government-private partnerships can achieve revolutionary things. The magnitude of the transcontinental railroad project and its strategic importance to the U.S. made it an excellent project for the first government-private partnership. Its success would lead to much more of this same design. The government was able to define and enforce standards like track width, endpoints and route. The exclusive license for just two companies and the guarantee of government backing enabled the UP and CP to borrow large sums on the capital markets and attract the best people to the project. But operating as private companies enabled each company to innovate and push in a way that would not have been possible for a government project.

As sea freight tackles a difficult and global problem like decarbonization, the lesson here is to continue to work to create a public-private effort. It should leverage the government’s ability to levy charges or taxes, enforce standards and eliminate unnecessary duplication while harnessing the private sector’s ability to innovate and move quickly. I believe the recently proposed International Maritime Research and Development Board is a good starting point to implement these principles.

2. Head-to-head competition generates speed and innovation. The race between the UP and the CP to build as much track as possible led to historic productivity and innovation. The CP laid more than 10 miles (16 km) of track in a single day in a record never matched again. The profit motive and a team’s desire to be “the winner” were powerful motivators that caused each company to find a way to eliminate every roadblock encountered and complete the job.

When leaders in the sea freight industry look for the ideal business structure to generate optimal results, they should always look for at least two competitors, except in the area of standard setting. There is no better way to drive innovation and speed than the threat of being second and the lure of having the bragging rights of being first.

3. New knowledge enables revolutionary accomplishments. The transcontinental railroad likely would not have been built in 1869 if not for the recent invention of the telegraph. This technology allowed instant communication between the frontier and the sources of manufacturing and finance in a way not previously possible.

The same thing can be said regarding the ability of both railroads to organize large groups of men and material effectively. The U.S. Civil War had taught Americans how to deploy men and material across large distances and this skill was a necessity for the task of building a railroad across the continent.

Leaders in the sea freight industry should be on the lookout for new technologies and knowledge that might make previously unsolvable problems now solvable. Companies can use open innovation platforms and processes to solicit help from outside of the industry as well as deploying their own R&D capabilities to this end.