In response to growing calls for more hours-of-service flexibility, the American Transportation Research Institute (ATRI) has published a technical memorandum on hours-of-service flexibility.

Produced by Jeffrey Short, senior research associate, the report concludes, to no great surprise, that truck drivers who travel during peak times are slowed and that more flexible HOS regulations could not only speed those travel times, but also would not impact the miles drivers cover in a day.

“On a national scale, HOS flexibility has the potential to decrease the number of hours it takes to complete the 273.9 billion miles driven by combination trucks annually in the U.S. While the total miles driven in the U.S. is a static figure – the marketplace requires this scale of goods movement – the overall driving time needed to deliver these goods can decrease if congestion can be avoided,” Short wrote.

The examination looked at a 585-mile route that included a 40-mile stretch through Atlanta that ATRI determined was a “representative freight-significant” corridor. Using this, and then comparing GPS data of 3,600 truck trips through this area along with travel times by hour of day and the operational costs as studied in ATRI’s annual Operational Costs of Trucking. The result is that HOS flexibility could result in time savings through this corridor – specifically the 40-mile stretch – of up to 1 hour, 15.5 minutes on the 14-hour clock.

More specifically, utilizing a 4-hour flexible HOS break window would result in “45.5 minutes less driving time because a 4-hour rest break allowed the driver to avoid a relatively small (40-mile) segment of urban interstate during peak travel times. If only 25 truck trips per day avoided the congested weekday time period presented on the study segment, truck drivers would drive 4,700 fewer hours annually to move the same goods the same distance.”

The report noted this savings, based on just 25 trucks, would be over $300,000 per year. Extrapolated across the country, ATRI believes using this 4-hour window would result in 2.3 million fewer hours driving and over $150 million in direct savings, not including other societal benefits.

“There is a clear benefit in driving fewer hours to move the same distance – drivers spend less time operating in less-than-ideal conditions while at the same time decreasing industry operating costs,” the report said.

Providing flexibility also gives the drivers the opportunity to avoid peak traffic hours, ATRI noted. The current 8/2 split does not afford drivers enough time to avoid congestion because peak traffic often lasts more than 2 hours in most locations. The result is that the 8/2 split’s benefits are limited and more flexible options are needed.

“There are however innovative HOS concepts that, if implemented, would enable drivers to avoid congestion by taking periods of rest,” the report pointed out. “For instance, a rest period of three or more hours that qualifies toward the daily 10-hour rest requirement could effectively help drivers avoid slow-moving peak travel periods. Without such an option, the current HOS rules will continue to encourage long-haul drivers to operate during peak periods of congestion.”

ATRI looked at 7/3, 6/4 and 5/5 split sleeper scenarios, each of which would pause the 14-hour clock but would equal the current 10-hours of mandated rest, just not consecutively.

“It is believed that these options … would allow drivers to avoid some of the nation’s worst congestion while at the same time allowing CMV operators to drive for less time to achieve the same miles and related compensation,” ATRI said.

To help in its calculations, ATRI utilized average speed data along routes to determine the best and worst times to travel certain corridors and no surprise, AM and PM peak times were among the slowest travel times, adding as much an additional hour of travel times in some cases. Along the 40-mile stretch in Atlanta, there is a difference of 53.5 minutes of travel time between the best and worst travel times.

Using operational costs, ATRI determined the cost difference between crossing this stretch at 1 a.m. versus 4 p.m. is $56.79, with it costing as little as $42.32 between 1-1:59 a.m.

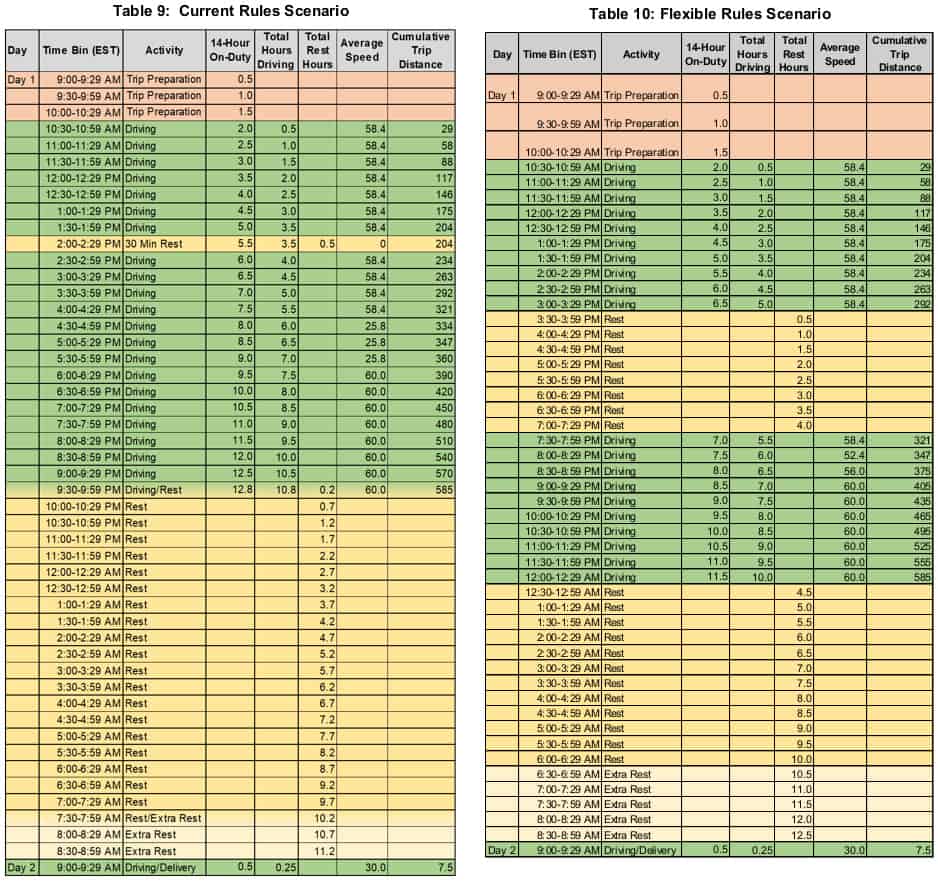

Using all this data, ATRI looked into the different HOS flexibility options. For purposes of this analysis, ATRI utilized a hypothetical driver who leaves Burlington, NC, at 10:30 a.m. on Day 1 and must stage the vehicle 585 miles away in western Alabama for a morning delivery. This route takes the driver through the 40-mile stretch of Atlanta used to determine the costs earlier. ATRI used approximately 60 mph as the average speed of the vehicle (58.4 mph to the east of the study area and 60 mph to the west; this includes time spent looking for parking during break periods).

Under current rules, ATRI describes the driver’s day this way:

“In this scenario the driver enters on-duty status at 9 a.m. and conducts pre-trip/load activities for 1.5 hours, leaving Burlington, NC at 10:30 a.m. The driver averages 58.4 mph for the first 3.5 hours of drive time, and finds a location to take the required 30-minute rest break after 5 hours on-duty.

The driver continues the trip after the 30-minute rest break, entering the congested 40-mile study area at 4:30 p.m. when the average speed is 25.8 mph and the additional marginal operating cost of travel (beyond free-flow speed costs) through the study area due to traffic delay is approximately $53.00. The driver then spends approximately 1 hour, 30 minutes to travel across the 40-mile corridor averaging 25.8 mph.

The first day of travel comes to an end at 9:45 p.m. with a pre-planned stop at a rest area near Boligee, AL. The driver enters a 10-hour rest period with 1 hour, 14.5 minutes of remaining on-duty time and 14.5 minutes of available drive time. Any unexpected delay would likely have prevented the driver from arriving at the pre-planned rest area.

The following day (Day 2) the driver must start at 9:00 a.m. (EST) to reach the delivery appointment on time.”

Using a 4/6 split sleeper berth, here’s how that scenario would change:

“The driver departs at 10:30 a.m. As the driver nears the congested study area, and as rush hour approaches, the driver stops for a 4-hour rest period. This is after driving for 5 hours and being on-duty for 6.5 hours. This stop allows the driver to avoid congestion and also covers the required 30-minute rest break.

As a result of the 4-hour rest period the driver is specifically able to avoid the congested travel period of 4:00 p.m. to 7:59 p.m. when average speeds can be as low as 25.8 mph. At 7:30 p.m. driving resumes after 4 consecutive hours of rest, and the driver enters the study corridor at 8:00 p.m. when the average speed to cross the corridor is 52.4 mph. After traveling through the study area the driver averages 60 mph. After 10 hours of total driving time Day 1 comes to a conclusion with the planned stop near Boligee, MS at 12:30 a.m. (EST). The driver takes a second rest period of 6 hours, accumulating a total of 10 hours of rest time by 6:30 a.m. (EST).”

Compared to the current scenario, benefits would also accrue under a 7/3 or 5/5 scenario, ATRI said.

“For the flexible scenario, the application of the 7/3 and the 5/5 split rest break both have better outcomes than those of the current scenario,” it wrote. “Both the 7/3 and 5/5 ensure that average travel speeds through the study area are at least 49 mph (instead of the 25.8 mph average in the Current scenario) and allow for completion of travel through the study area in less than an hour. It should be noted also that the 2-hour break which currently does exist would at best allow for average speeds of approximately 37 mph within the study area in this scenario.”

“Trucking is not a one-size-fits-all industry. Truckers in the U.S. begin a day of work in thousands of different cities and towns, and drive to myriad destinations as they crisscross the nation. No two trips are the same; even with identical origins and destinations, congestion on most trips varies due to time of departure, ultimately resulting in a variety of travel times. The opportunity for a driver to adapt to changing conditions and congestion levels throughout a day is critical, and could be greatly enhanced with the addition of flexible sleeper berth rules to the current HOS regulations,” Short concluded.

Help the driver

There should be a change overall.Who came up with 11/14 hos recommendations anyway. Obviously it wasn’t a truck driver a lot of people work 12 to 14 hour shifts in logistics. Picture this increase the Hos to 14/17 give them a 2 hour break or split the break and maybe 8 or 10 hours off duty. Depends on the break will affect off duty hours. A driver will be able to get anywhere and have rest. Everything will still fall to 70 hours but done in five days. The on duty not driving bs has to be use a little different like emergency situations or breakdowns and repair situations or you 100 miles or less to destination with required breaks something has to change. Higher pay that’s not happening and to have drivers racing to catch up on time to make ends meet is ticking time bomb. Help the driver not stress the driver they want to be home like everyone else,not some pissy over crowded truck stop!!!!!!!!!???⛟

Billy Grissom

This is a great article this happens in every major city because of the 8 /2 split. If they change it it needs to be 5/5 split . The best way to get through Atlanta is at 12am no car traffic and it is just trucks. Stop at 1pm go to sleep leave at 11pm works every time .

Nice job on the the article now get

Washington to change hos.

Macman

David Eastburn

This is what truckers have been doing for years…..and regrouping the hours on a log book to make it fit,. Which they call "cheating". Of course nobody has determined exactly who is being cheated. Since normally the load gets picked up and delivered on time, or usually ahead of schedule, which leaves time for another "undocumented" rest break. I don’t understand the big problem with allowing the driver to determine when he or she needs a break,. In 47 years of trucking I have never had an employer or dispatch say they would rather take a chance on a crash than to allow a driver to take a rest break. We know what to do. We don’t need or want some electronic tattletale dictating what common sense already dictates..