Beyond just sheer capacity, one of the major advantages larger carriers have over smaller fleets and owner-operators is the ability to handle drop-and-hook freight. Drop-and-hook freight involves a trailer that is pre-loaded and simply picked up and dropped at another location. Truck drivers love it because it maximizes their driving time and leads to more loads and more revenue.

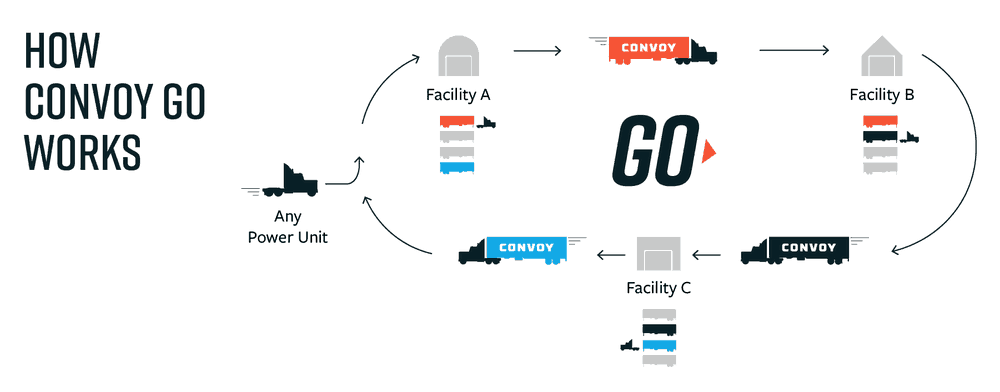

Convoy, which has helped revolutionize the load board business, is now expanding nationwide a trial program first launched in 2017. Convoy Go will utilize a Convoy trailer pool and allow owner-operators and small fleets to take advantage of power-only loads.

“In the past I was able to do three to four loads a week per truck but now, with Convoy Go, I can consistently do six loads per week per truck,” said Eduardo Canales of Canales Trucking, which has trialed the program. “We are a small company with two trucks and, in the past, we rarely did power-only loads. Now, we operate almost exclusively power-only loads with Convoy. The main upside is that the wait time is very short; we are in and out of facilities in 45 minutes versus more than four hours for live loads. Also, Convoy allows us to have power-only headhauls and power-only backhauls which allows us to work more miles.”

Tito Hubert, product lead for Convoy Go, told FreightWaves that the average wait time for truckers using Convoy Go is less than an hour, helping drivers get in and out of facilities quicker, which leads to more time on the road. Nationally, according to FreightWaves’ SONAR data, the average wait time (WAIT.USA) for drivers was 2 hours, 28 minutes on March 31, 2019, up from 2 hours, 15 minutes on March 31, 2018.

“We are giving access to any carrier or owner-operator to operate like an asset-based carrier,” Hubert said. “Today, the main carriers taking advantage of this type of freight are asset-based carriers because they have the [financial] capacity” to buy trailers and leave them at facilities.

Convoy is utilizing its growing Universal Trailer Pool of leased trailer assets to build the program and make these opportunities available to owner-operators and small fleets. Initially focused on select carriers and shippers, Hubert said the time is right to expand the program nationally.

“It is built on density and we will continue to build density,” he said. “Any shipper in our network that is doing a lot of loads can do drop with us.”

Hubert said that when it was first introduced, Convoy provided a select number of trailers to shippers to use, leaving those assets with the shipper.

“We definitely learned a lot along the way,” Hubert said. “One thing that was interesting was at the beginning we started with a dedication of trailer pools to shippers and we found we were not finding the efficiencies we thought.”

The company shifted the program and now utilizes trailers that float between shippers, giving Convoy more flexibility to meet demand, especially in terms of backhauls.

“We have a routing system that allows us to balance the trailer pool based on future needs,” Hubert said. “We do have couriers taking trailers from Point A to Point B. A key part of this undertaking is having the trailer move in a smart way to a new destination to [allow it to be used].”

In some cases, drivers may be paid to reposition an empty trailer, although Convoy is working hard to ensure trailers don’t move empty. When possible, Convoy allows the driver to use the trailer to pick up a live load if it moves that trailer closer to a destination where it will be needed for a Convoy Go load.

There are no fees or other charges for drivers using the program, including those that may pick up a live load. The goal is simply to help owner-operators maximize their driving hours and earning capability.

“We have backhauls that allow these owner-operators to do round trips and come back to their trailers,” Hubert said. “We have drop backhauls where you come back to Point B and you drop [the empty trailer] and we also have the ability to haul live loads.”

With local, regional and long-haul opportunities in the program, the hope is that those interested in power-only will find loads that suit their needs.

“The thing we’re really excited about with this program is battling waste,” Hubert said. “We know there is a lot of waste in the system. About one-third of transportation cost is due to waste [with time spent waiting for appointments or to load or unload the primary cause]. We think opening up this drop-and-hook [freight] to owner-operators [eliminates some of that].”

Hubert said that Convoy Go loads usually have five- to 10-hour appointment windows and can increase carrier productivity by up to 50 percent. Drivers can access all Convoy Go loads through the Convoy app simply by selecting “power-only” as an option.

Shippers must move a minimum number of loads to participate, and simply need to notify Convoy of how many trailers they will need so the company can position assets accordingly. Unilever Logistics is one of the shippers that tested Convoy Go with great success.

“Convoy has been recognized by our Operations team as being consistently able to provide us capacity in a larger scale in tough times compared to some of our partners,” Fernando Bono, Unilever Logistics’ transportation manager, said. “In the past, that extra capacity was exclusively live, which presented challenges during loading at our plants and unloading at our customers. With the implementation of Convoy Go and consequently the expansion of drop capacity, those challenges have vanished and Convoy can provide the capabilities and service needed to our plants and customers with reduced risks to the operation.”

Any trucker or shipper utilizing Convoy Go would receive the same guarantees that all Convoy loads enjoy, so it really becomes a question of what type of load does the trucker want to haul?