Flexport, the San Francisco-based digital freight forwarder, announced today the release of the second version of its platform. The new online portal is the product of a year of conversations Flexport operators and engineers had with more than 100 customers, and it reflects what those customers cared about.

Frank te Pas, senior product manager at Flexport, said that three major themes emerged from those customer conversations: customers wanted the ability to streamline their workflows; the ability to seamlessly connect specific shipments to business priorities; and better collaboration between shippers and their suppliers.

For Flexport, streamlining their customers’ workflows allows those customers to easily find the work that needs to be done and eliminates repetitive tasks like entering multiple shipment numbers into a search bar to find all shipments related to a specific event. In general, te Pas said, Flexport’s goal is to leverage its technology and the expertise of its logistics teams to let its customers focus on complex decisions that will grow their businesses.

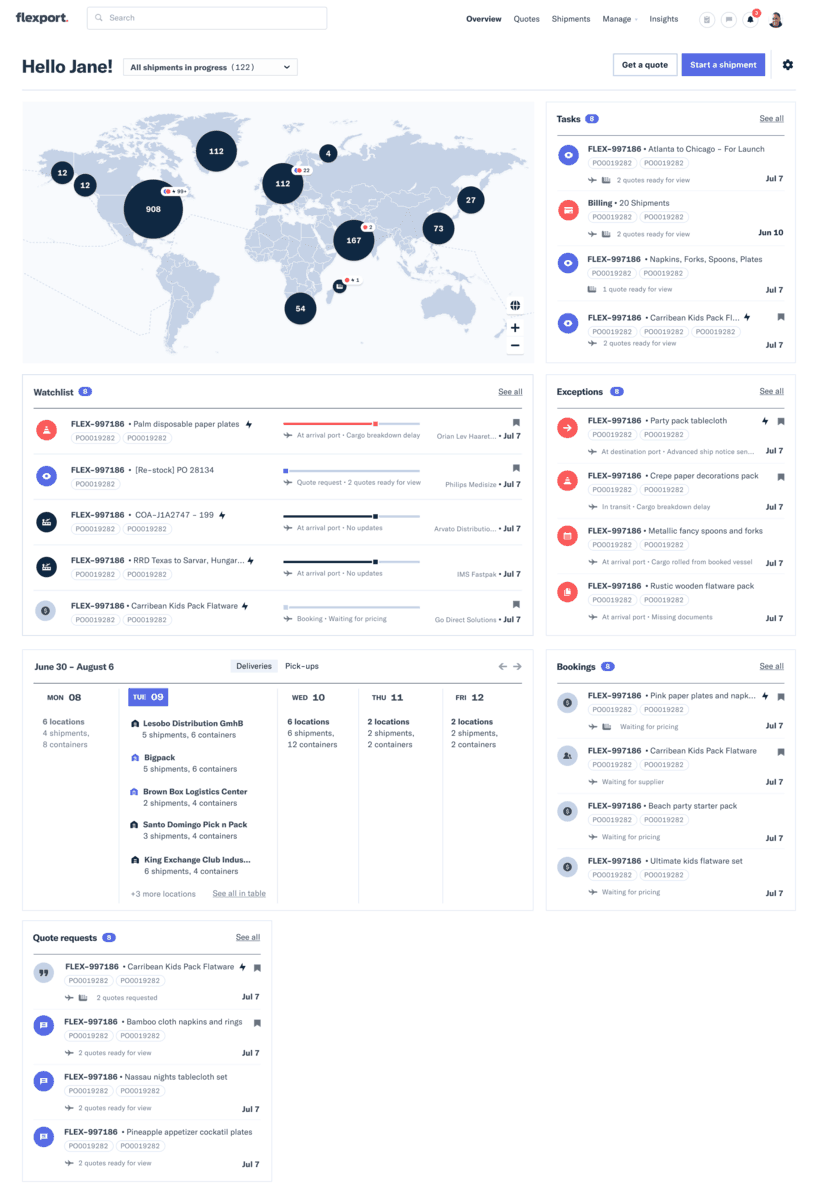

In the second version of its platform, Flexport displays exceptions notifications across multiple widgets like the map view and schedule view, and context from the Flexport team is included with the notification to help users quickly reach a decision.

How Flexport thought about tagging shipments with business priorities was very impressive. In the demo that te Pas gave to FreightWaves, the example was a fashion company preparing for a fall launch of new styles in multiple locations in North America.

Any shipment in the world related to that business priority could be tagged ‘for fall launch’ and marked as high priority by the customer. Then the customer could search for ‘fall launch’ – or even a misspelling of that phrase, since Flexport’s new search feature is field-agnostic and intelligent – and quickly see the status of all shipments related to that business priority. Insights and reports can be generated on the basis of those tags, isolating specific company initiatives and projects from the rest of the freight flowing through the customer’s supply chain.

Based on initial pilots conducted by Flexport, customers can save 30 to 40 percent of the time it takes to find the insights they’re looking for by using custom tags.

“Subsequent actions can occur when you tag a shipment,” te Pas explained. “You can understand the status of all shipments with a certain tag through APIs, and across end-to-end shipment lifecycle you can automate the more standard workflows. You can automatically ingest bookings and purchase orders, and further downstream you can extract shipments and status and put them in your system. By using specific, custom references your systems can take action if something happens, with replenishing inventory for example.”

Collaboration is also a vital part of Flexport’s value proposition to its customers, especially because it aspires to be ‘the operating system for global trade.’ te Pas said that collaboration within companies is just as important as collaborating between shippers and their suppliers, noting that some of Flexport’s customers have on-boarded 100 or more users onto Flexport’s platform.

While each of those logistics professionals may only have responsibility over a certain part of a shipment’s life cycle, the decisions they make sometimes need to be visible across business units and should be pushed to relevant supervisors in an intelligent way.

But collaboration between companies has the potential to unlock even more value. Flexport’s new platform allows information entered by suppliers to be pushed to the customer and the customer’s carriers automatically.

Flexport’s early tests have found that the average time it takes to complete shipper

documentation on its platform is almost 60 percent lower compared to suppliers transmitting the same information through email. What’s more, because Flexport’s platform contains a dynamic single source of truth, the quality of the data tends to be four to four and a half times better, in terms of the reduced number of errors.

As a shipment is built, and pick-up times or dimensions like volume and weight reported by the supplier change, the shipper can stay abreast of the developments and make adjustments in real-time.

Flexport’s new look and functionality are impressive, especially because the company has shown that it can quickly ship new software in response to customer needs even as it has reached scale. In February, the digital forwarder raised $1 billion in a venture capital round led by SoftBank Vision Fund and achieved a $3.2 billion valuation. In an industry where competition on price can be be stiff, Flexport’s efforts to help its customers deepen relationships with their partners should be viewed as a meaningful differentiator.

David

Can someone ask Flexport to integrate their loads intro AscendTMS please. We get all our OTR loads from inside Ascend but Flexport loads aren’t in there yet 🙁