Solar power may not be the cure-all for reducing fuel costs, but it can provide assistance and achieve payback in relatively short time if used in the right applications, according to a new Confidence Report from the North American Council for Freight Efficiency (NACFE).

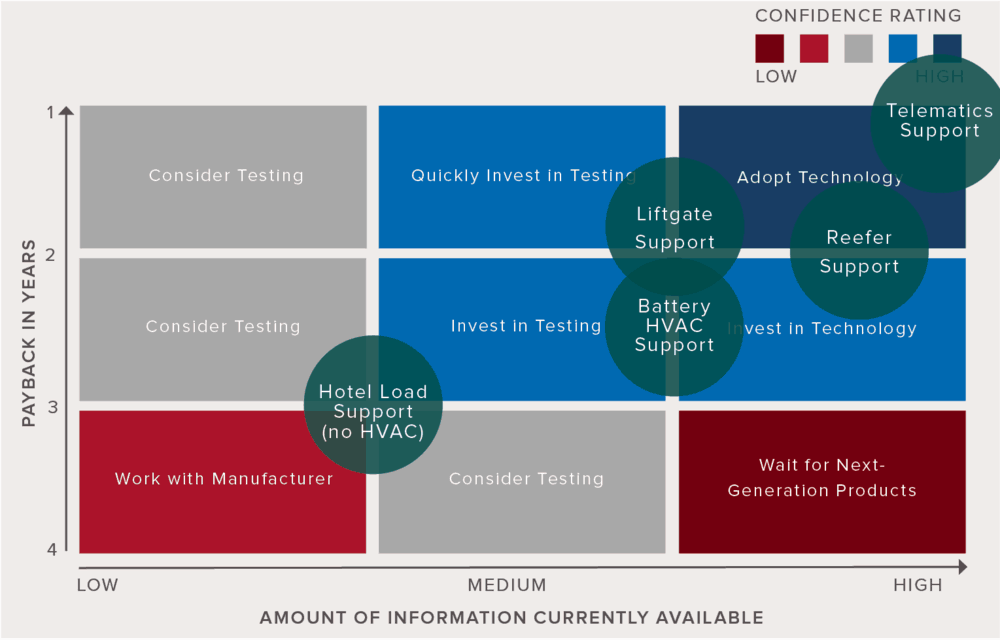

Working with the Rocky Mountain Institute, NACFE’s 16th Confidence Report, “Solar for Trucks and Trailers,” lists high confidence in a 1-year payback when solar power is used to support telematics operations. There is also a high confidence from the NACFE team that solar investment provides a return on its investment in about two years when supporting refrigeration applications and medium to high confidence of a payback in that same timeframe when used for liftgate operations. Battery powered HVAC support also should provide a payback within three years.

The only area where the payback was longer term – around 3 years – and less certain was in hotel load support with no HVAC operations, the report stated.

“What we found is it does have a real good place here; cost has come down and durability has come up,” explained Mike Roeth, NACFE executive director. “That flexible mounting has really improved, as well as the performance of these panels.”

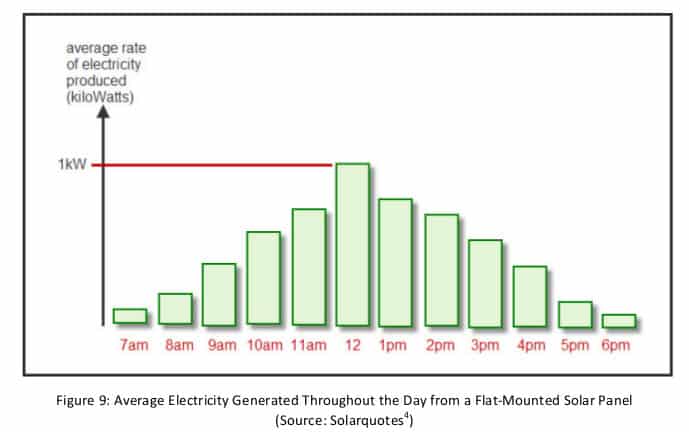

In a conference call with reporters, Roeth said that fuel savings for solar panels are generally quite small and depending on the areas the truck runs can vary greatly, making definitive conclusions difficult. The intensity and panel angles in relation to the sun, time of day trucks run and the locations they park all play a factor in how much energy is collected.

Despite all this, though, using solar panels on tractors or trailers can be beneficial.

“There are a lot of options for these solar packs,” Roeth said. “It’s really important to understand what the problem is you’re trying to solve for … and size those panels right for the use.”

In a best-case scenario, a 300-watt solar panel could produce the energy equivalent of an additional battery, the report found. This translates into about an additional 1 ½ to 2 hours of power before the engine would need to be started to charge the batteries. The savings themselves may not be significant over the cost of a year, but solar panels can save the purchase of additional batteries or even roadside service calls due to dead batteries, NACFE noted. The group noted that it believes jump starts could be reduced by 30% to 50% over the cost of a year because of solar panels.

The report noted that time of day, location, and of course, weather conditions impact the amount of energy a solar panel generates. Even under the best conditions, though, NACFE said the panels can’t supply the necessary current to drive large tractor loads like battery HVACs and refrigerators, but they can provide supplemental power.

NACFE has two locations on its website where fleets can input their individual operational conditions to determine if solar panels might be a fit for their operations.

Traditionally, solar panels have been used to help power HVAC systems and other hotel loads. The thin, flexible nature of the panels allows them to be to installed in many places on tractors, including the underused roof fairings and hoods, areas that have direct access to sunlight.

Battery HVAC systems offer a significant benefit to fleets to provide cab comfort without idling the tractor. NACFE said that solar panels can extend the runtime of these systems to “not only to help the HVAC system make it through the night without draining the truck’s batteries, but also to reduce the load on the alternator the next morning, resulting in fuel savings. The solar system can extend the life of the batteries and dramatically reduce, if not completely eliminate, costly roadside assistance calls for dead batteries.”

For day-to-day living in the truck, solar panels can provide the necessary power to run items such as refrigerators, TVs, coffee pots and microwaves in addition to small electric devices.

“The combined load of all of these devices might only be sustained for about eight to 10 hours by a truck’s batteries before reaching a critically low voltage. Solar panels can augment the energy coming from the truck batteries and maintain the batteries at a higher state of charge, extending the battery life and increasing driver comfort by allowing hotel loads to operate for longer periods of time,” the report noted.

Even trailers are now benefiting from solar power. Liftgates, telematics and refrigeration units can all draw power from solar, taking some of the load off existing batteries. Panels might also allow for the elimination of a DC-DC voltage converter to boost the voltage to the trailer batteries, NACFE’s report points out.

Like many technologies, if you jump before you walk, you will fall. Before adding solar power to your fleet, you must evaluate the overall benefits, NACFE says. Factors such as total energy produced, fuel saved, wear/panel life, battery life extension, and a fleet’s total energy profile need to be considered when determining the total cost of ownership of solar panels. Consider:

- The historic number of roadside assistance calls to jump-start or replace batteries

- Area of the country in which the vehicle predominantly Operates Specifically for tractors

When considering these, fleet owners should consider cost savings from items such as reduced idling, extended alternator or battery life, and emergency roadside assistance costs related to these wear items. Driver satisfaction might also factor into the consideration.

One factor many fleets overlook is the lifecycle of solar panels. Often, the panels will outlast a fleet’s trade cycle for that unit and whether that panel will be removed or traded in with the vehicle needs to be considered.

The consideration for trailers is a bit different, as the inclusion of electrical requirements for liftgates, refrigeration units, telematics, lighting, and pallet jack charging need to be considered. The duty cycle the trailer electrical system will encounter also should be part of the equation. Of course, roadside assistance costs related to trailers could be saved as well.

Because fleets typically keep trailers for longer periods of time, the investment in solar panels can be spread out more on this equipment, resulting in a different ROI consideration.

Given these conclusions, NACFE believes that fleets should seriously consider investing in solar systems.

“We think the application of solar panels on trailers with extra electrical loads like telematics, refrigeration units, and liftgates make sense as a means of improving battery life and reducing the need for roadside assistance,” the report recommended. “This is especially true if the trailer spends long periods without being attached to a tractor. And the opportunity to extend the run time of battery HVAC systems makes installing solar for battery HVAC support a good solution.”

One key is sizing the system accordingly. The report noted that when truck batteries are fully charged, all of the solar output can’t be used. “For this reason, it is generally recommended to size a solar system not to the available area for installation, but rather to maximize the value of the output based on the typical electrical load of the truck,” the report pointed out.