Each year, truck drivers and fleets face both announced and unannounced inspections or enforcement blitzes. The big one is always International Roadcheck, scheduled for June 4-6, 2019, in North America. During this 72-hour blitz, an average of 14 vehicles per minute are inspected – with over 60,000 inspections conducted during this time.

In 2018, 67,603 total inspections took place with 21.6 percent of all inspected motor vehicles and 3.9 percent of drivers placed out-of-service (OOS). Last year, hours-of-service (HOS) compliance was the focus of Roadcheck. Despite announcing this beforehand, 43.7 percent of all drivers placed OOS were because of an HOS violation.

Out-of-service orders negatively impact a carrier’s Compliance, Safety, Accountability (CSA) Behavioral Analysis and Safety Improvement Category (BASIC) scores which could lead to a compliance review and may ultimately affect a carrier’s Safety Fitness Determination rating, the Commercial Vehicle Safety Alliance (CVSA) noted. Other consequences of an out-of-service order could be delivery delays, lost driver wages and revenue, and potentially lost customers.

As Roadcheck 2019 quickly approaches, how can fleets and drivers stay compliant and on the road? It starts with being proactive.

Passing inspections is the result of being prepared, knowing what documentation the driver must have available, and maintaining equipment that conforms to regulations.

CVSA inspectors conduct one of eight levels of inspections, ranging from a complete driver and vehicle inspection, to inspection levels with a more specific area of focus, such as one for radioactive materials and the newest, but not yet widely used, fully electronic inspections. Depending on the chosen level of inspection, the inspection could include up to 37 steps.

A complete driver and vehicle inspection is the most comprehensive and comprises the majority of inspections during Roadcheck. Inspectors will check drivers for operating under the influence of drugs or alcohol, fatigue or illness, and using a seatbelt. The officer will also ask the driver for the following:

- Driver’s License

- Medical card (if a non-CDL driver; if a CDL driver the officer will verify the medical qualification information on the driver’s MVR)

- Hours-of-service records (logs, electronic or paper if an exemption applies)

- Proof of the vehicle’s annual inspection

- The vehicle’s registration and fuel permit (if required)

The officer will verify that the company’s credentials are valid and then, upon doing so, continue on to inspect the vehicle. Among the items checked will be:

- Lights

- Brakes (including all mechanical components, low-air warning, ABS, and tractor protection valve/trailer breakaway brake, if required)

- Windows, windshield, and windshield wipers and washer

- Fuel system

- Coupling devices

- Tires, rims, and hubs

- Defroster

- Mirrors

- Horn

- Bumpers

- Emergency equipment (fire extinguisher, warning devices and spare fuses if required)

- Cargo and equipment securement

- Frame

- Driveline/driveshafts

- Suspension

- Steering (including mechanical components and wheel lash/freeplay)

This year, Roadcheck inspectors will pay particular attention to steering and suspension components. While other maintenance items should not be ignored, steering and suspension should be a focus for any maintenance department ahead of this year’s Roadcheck.

During 2018’s Roadcheck, CVSA inspectors handed out 537 steering-related violations and idled 286 vehicles with OOS notices. There were 500 suspension violations and 538 suspension-related OOS citations issued.

J.J. Keller provides safety and compliance services, including electronic logging devices and driver vehicle inspection reports through its Encompass® DVIR app, and advises fleets to train drivers, driver management personnel and maintenance personnel on the ins and outs of inspections before Roadcheck.

Preparations should include making sure the driver is fully qualified and has all his/her credentials and other paperwork prepared for an electronic log roadside inspection. This includes logs, print or electronic, for the current day and the previous seven days; that the current day’s log is up to date; and that the driver follows road rules including wearing his/her seatbelt with no speeding or unsafe driving. The driver should also inspect the vehicle regularly – including thorough pre-trip, en route and post-trip inspections – and see to it that defective items get fixed; and that cargo and cargo securement devices after the cargo is loaded are checked before and throughout the trip.

“One of the best ways to avoid vehicle violations at roadside inspections is to do a thorough pre-trip inspection of the vehicle before the vehicle leaves the yard. Any defects in the equipment should be addressed and repairs made to correct the items before the vehicle is driven,” Tom Bray, transportation industry consultant for J.J. Keller, said.

The company also offers a suite of consulting services, including safety and compliance programs, training and audits, and assessment service, as well as an online Roadcheck Resource Center and 2019 Roadside Inspection ebook, that is available for download at jjkeller.com/roadsideguide. The company’s offerings include information on the Federal Motor Carrier Safety Regulation (FMCSR) compliance checks with CSA BASICs as a focus. Compliance with the BASICs provide a fleet a good foundation for passing a vehicle inspection.

Will Schaefer, director of safety programs for the Commercial Vehicle Safety Alliance, noted that there are three U.S. Federal Motor Carrier Safety Regulations (FMCSRs) in play when it comes to steering and suspension systems: 393.209, 393.307, and 396.3(a)(1).

Not all violations in these areas require an out-of-service order. Shaefer noted OOS criteria for steering includes steering wheel lash well beyond the specifications in 393.209, as well as components such as the steering column, steering gearbox, pitman arm, ball and socket joints, tie rods and drag links, and other components, which must be free of cracks, missing fasteners and excessive looseness.

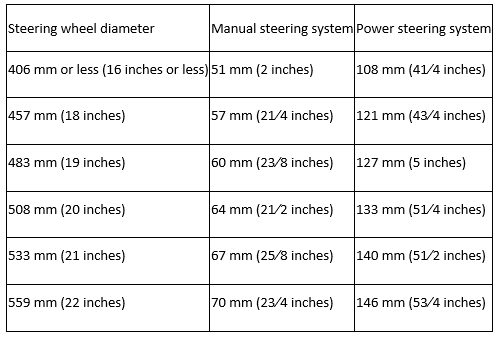

Steering wheel lash specifications are defined as:

For steering wheel diameters not listed, the steering wheel lash “shall not exceed 14 degrees angular rotation for manual steering systems, and 30 degrees angular rotation for power steering systems,” CVSA said.

CVSA has produced an inspection bulletin covering how to inspect rack and pinion steering systems (see 2010-03 here: https://cvsa.org/inspections/inspections/inspection-bulletins/).

On suspensions, the OOS criteria generally note that certain axle components and spring assemblies should not be broken or cracked, air suspension air bags should not be deflated, connecting rods, tracking component assemblies, and sway bar components should not be cracked, loose, broken or missing, Shaefer told FreightWaves. On sliding trailer suspension systems, locking pins should be properly engaged and the sliding suspension members should be free of serious cracks along attachment welds, as defined in the criteria.

CVSA produces a North American Standard Out of Service Criteria handbook (https://cvsa.org/inspections/inspections/out-of-service-criteria/) that covers out-of-service conditions.

Steering and suspension systems, like other maintenance issues, shouldn’t trigger an OOS violation for a vehicle, if they are regularly maintained and inspected prior to driving the vehicle. Prevention is the best medicine, even for commercial vehicles.