SAN LEANDRO, Calif. — How the Penske box truck managed to jump a concrete road barrier on Interstate 880 didn’t matter to other motorists stuck in the 20-minute traffic jam it caused.

The wreck was an unexpected highlight of a ride in Embark Trucks’ high-autonomy truck around the East Bay on a sun-drenched Thursday morning last week. The ride was supposed to take about an hour and 10 minutes. It lasted 1:45.

Embark invited FreightWaves to experience the state of the Level 4 Embark Driver software it plans to sell to fleets that order from major truck manufacturers beginning around 2024, the year most of its competitors expect to launch driverless trucks.

Other than a small screen in the dash indicating autonomous engagement, the truck interior is identical to a stock model. A large black 2½-foot tall box containing the super-powered computer unit that is the robot’s brain was installed in the sleeper portion of the truck.

Robot driving

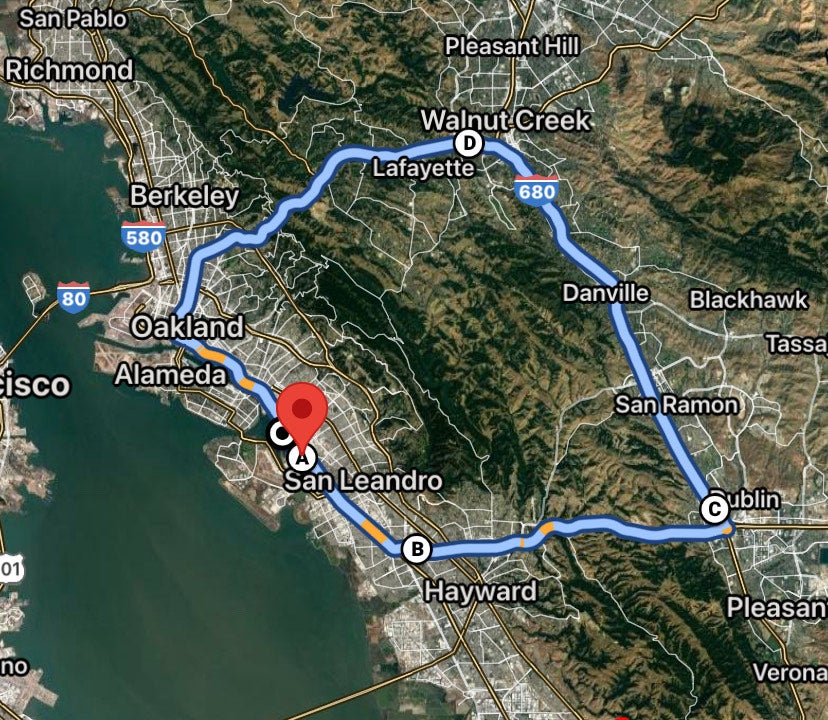

With the autonomous system engaged, the 2020 Peterbilt 579 exited a parking lot, drove about five blocks on surface streets and entered an I-880 on-ramp at Hegenberger Road in Oakland, following a route around the East Bay.

Embark Driver smoothly handled the stop-and-go and lane jockeying, reacting to drivers darting into its lane and moving lane to lane as openings appeared. The rumble of the diesel engine combined with voices muffled by face masks required speaking loudly.

“What we’re doing here is going to represent the hardest stuff you might see over many full days of driving packed into an hour,” Embark co-founder and CEO Alex Rodrigues said.

In the passenger seat next to safety driver Beverly Morrison, Rodrigues occasionally wrote notes on a laptop and narrated the journey. Video screens embedded in the backs of the driver and passenger seats were equipped with a visualizer that showed what the truck was seeing in real time.

Rodrigues has hosted dozens of autonomous demonstrations in recent years. He had no idea how challenging this ride would turn out to be.

Minutes after merging onto the interstate, traffic began to crawl, similar to rush hour earlier in the morning. After several minutes of full stops followed by inching forward, Rodrigues asked rhetorically: “Wow, what is going on? The truck is doing great, but the road …”

Uh-oh, accident ahead

As the slow-motion ride dragged on, Cowen Inc. analyst Jeff Osborne, seated with me in the rear of the cab, punched up the traffic conditions on his phone. “Accident 1,000 feet ahead,” he reported.

Navigating a crash scene is one of five challenges remaining for Embark as it readies its plug-and-play autonomous system for installation on trucks from the Big Four truck makers: Freightliner, Volvo, Paccar and Navistar International.

Embark has checked off 11 things it needs to safely operate without a driver. The remaining challenges to removing the driver are: pulling over to safety; emergency vehicle interactions; evasive and emergency maneuvers; inspections; and blown tire and other mechanical failures.

“None of our competitors have demonstrated any of those five,” Rodrigues said. “We’re a little more up-front in setting out the plan.”

Finally reaching the tangled and mangled Penske vehicle, our truck began looking for a way to avoid police and emergency vehicles — one of the items on Embark’s to-do list.

Morrison, a 25-year veteran driver who used to haul a fuel tanker, decided to take over the truck’s operation, disengaging the Embark Driver as a police officer paced onto the accident scene directly in the lane. Making those calls is her job.

“Cruising down the highway is the easy part for this truck. But we want to put it through these places where we know we’re likely to get accidents and slowdowns. That’s what we’re working on having it handle. The more practice we give it the better.”

Embark co-founder and CEO Alex Rodrigues

“I had to go beyond that onto the shoulder to make sure I gave that police officer extra room,” she said. “So I’m going to take us beyond our norm.”

The truck probably could have gotten through the scene without human intervention, Rodrigues said. But probably is not good enough when pedestrians are involved.

Disengagements are increasingly rare. Observers witnessing one is even rarer.

Back in business

Minutes later, with Embark Driver reengaged, the system smoothly navigated the now wide and clear 10-lane highway, approaching an off-ramp and steep curve. It easily hauled its 53-foot trailer with 25,000 pounds of test weight into a cloverleaf interchange onto Interstate 580.

The next wow moment came as we reached the Caldecott Tunnel, an east-west highway tunnel through the Berkeley Hills between Oakland and Orinda built in 1937. The tunnel blocked the truck’s GPS signal, forcing it to rely solely on sensors to stay on the course from light to dark and back to light.

Less noticeable but just as important for robotic operation was the truck’s ability to follow active road resurfacing where the open-source map being used does not align with what is painted on the actual road surface. Embark’s Vision Map Fusion technology relies on real-time sensor data to navigate the truck rather than high-definition maps, which can be inaccurate during roadwork or inclement weather.

A robotic voice twice advised Morrison to keep her hands on the wheel. It also orally approved gaps for lane changes and resumption of lane keeping.

“If the truck wants to make a lane change, it’s good that it gives the safety driver a heads-up so that they know what it’s doing,” Rodrigues said.

“Cruising down the highway is the easy part for this truck,” he said. “But we want to put it through these places where we know we’re likely to get accidents and slowdowns. That’s what we’re working on having it handle. The more practice we give it the better.”

Related articles:

Embark Trucks taps industry advisers on path to AV commercialization

Embark knits BYD electric trucks with its autonomous tractors for cleaner air

Nvidia will compute crushing loads of Embark Trucks’ autonomous data