Neither waning stimulus and extra unemployment benefits nor a peaking delta variant kept consumers from spending at a robust clip during retail’s fiscal third quarter, which ran through the end of October. The more notable takeaway from the period may be the amount of merchandise retailers took in as inventory growth significantly outpaced higher sales when compared to the year-ago quarter.

At first blush, it appears retailers have rebuilt depleted inventories after a sustained stretch of elevated consumer buying, signaling a boom cycle for trucking is nearing the end. Comments like, “We ended the quarter in great shape on inventory,” from Walmart (NYSE: WMT) among others, and Target (NYSE: TGT) signaling “a strong inventory position heading into the peak of the holiday season,” suggest the retail sector may be caught up from nearly a year-and-a-half run on most general merchandise SKUs.

However, this quarter’s heightened stock levels are somewhat distorted.

Retailers have been ordering merchandise much earlier than normal this year to meet what is expected to be record holiday demand and to avoid dislocation in the supply chain that is causing shipment delays. The group incurred higher freight costs to do so, with some even bearing the expense of chartering their own container ships to guarantee the stock needed for the biggest buying season of the year would be on the shelves.

The pull forward of inventory further boosted the year-over-year comparisons to depleted inventory positions from a year ago.

“There’s still uncertainty as we think about supply from Asia as different factories from time to time were closed,” said Target Chairman and CEO Brian Cornell. “And we’re just going to have to show great flexibility and agility to provide the products that our guests are looking for and our system requires as we plan for the next fiscal year.”

Another tell is that most retailers have yet to engage in any sizable promotional or markdown activity as merchandise is being delayed and remains tough to source. “Full-price selling” has carried through the pandemic, and management from virtually every chain said the fiscal fourth quarter — which normally sees the most discounting — will provide a limited number of deals.

Inventories are also reported in absolute dollars and reflect mid-single-digit price inflation, which is included in the increases. There’s inflation in the sales comps as well, but many retailers like Walmart have said they are eating some of the increased costs to win market share. Net-net, inflation likely benefited inventory growth rates more than the sales comps.

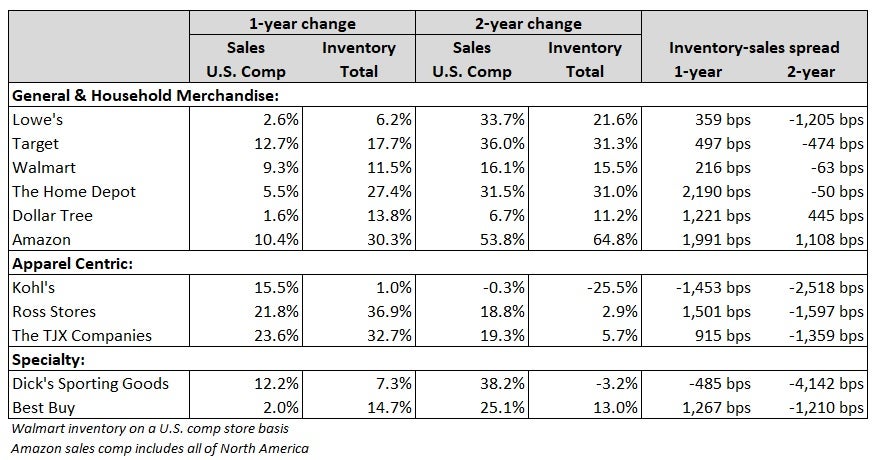

Inventory-sales spreads (the inventory growth rate less the sales growth rate) showed stock levels grew considerably faster year-over-year than sales at most major retailers during the first third quarter. But the comparisons to 2019 still show a deficit.

Ample merchandise for holidays but restocking long from over

Amazon’s (NASDAQ: AMZN) inventory-sales spread was up nearly 20 percentage points year-over-year.

The company is pulling forward holiday buying, offering some promotions earlier than normal. The goal is to avoid a late-quarter demand surge on its already-strained fulfillment and delivery capacity. Labor headwinds remain its primary challenge.

During the third quarter, Amazon was forced to ship inventory to facilities where labor was available to unload it. “This resulted in less optimal placement, which leads to longer and more expensive transportation routes,” CFO Brian Olsavsky stated on Amazon’s quarterly call.

Labor and related productivity headwinds, as well as general cost inflation, added $2 billion to operating costs in the period. The company’s guidance calls for $4 billion in additional costs during the fourth quarter — half in labor inflation with the rest tied to supply chain disruption and elevated transportation expenses.

Net sales are forecast to increase between 4% and 12% year-over-year, but operating income will be cut by more than half to as little as breakeven given the extra costs.

“In Q3, labor became our primary capacity constraint, not storage space or fulfillment capacity,” Olsavsky added.

Walmart noted its inventory increase, which only slightly outpaced sales growth, “in preparation for what we expect to be a strong holiday season,” CFO Brett Biggs told analysts on a call. “The steps taken to mitigate transit and port delays have positioned us well, including adding extra lead time to orders, chartering vessels for Walmart goods, rerouting deliveries to less congested ports and expanding overnight hours at key U.S. ports.”

Walmart’s fiscal fourth-quarter U.S. sales are facing a tough comp but still expected to increase 5%.

Target has been busy booking holiday purchase orders much earlier than normal as well. The company’s inventory grew 17.7% year-over-year, which outpaced sales growth by 500 basis points.

“While we continue to see some periodic outages across different items and categories, we are entering the holidays with a very healthy inventory position overall,” COO John Mulligan stated on a call.

It raised its fourth-quarter outlook, which now calls for high-single- to low-double-digit sales growth, up from the prior guide of a high-single-digit increase. However, it expects the inventory rebuild will continue into 2022 amid supply chain headwinds.

Target’s inventory-sales spread remains 470 bps lower on a two-year comparison.

The Home Depot (NYSE: HD) saw the biggest inventory increase relative to sales (2,200 bps). However, some of the additions were directed to stocking new facilities, including new bulk distribution and direct fulfillment centers, as it expands its nationwide coverage of same- and next-day delivery to 90%. On a two-year comp, inventory and sales have increased at a similar pace.

Lowe’s (NYSE: LOW) pulled forward merchandise ahead of the holidays and is taking the same approach toward spring buying. It is storing excess inventory in coastal-based warehouses to avoid stockouts. The actions drove its inventory-sales spread 360 bps higher year-over-year. The metric is still down 1,200 bps compared to 2019.

“Our push to land spring product earlier than normal has increased our inventory position modestly, and this approach also limits our ability to significantly improve inventory turns in the near term,” CFO Dave Denton told analysts.

Dollar Tree Inc. (NASDAQ: DLTR), the parent of discount chains Dollar Tree and Family Dollar, saw a surge in its inventory-sales spread in the period. However, the inventory increase included a considerable amount of merchandise still stuck on the water as past due deliveries are 4.5 times higher than normal at Dollar Tree branded stores.

The company reported 370 bps of year-over-year gross margin deterioration, which was “driven primarily by higher freight costs,” a press release read.

“While much of the focus has been on trans-Pacific ocean container rates, we are being impacted by all aspects of freight, including higher costs for inland transportation by truck and rail and higher diesel costs, CFO Kevin Wampler stated on a call. “Additionally, in the third quarter we moved more containers than originally planned, which required utilizing the spot market rates higher than forecasted.”

Management said elevated freight costs will shave off $2 per share in earnings during fiscal 2021. The company’s current earnings per share guidance is $5.48 to $5.58. It plans to recoup inflation going forward and return to historical gross margins of 35% to 36% in fiscal 2022 as it raises price points for its $1 product line to $1.25.

Apparel-centric chains Ross Stores (NASDAQ: ROST) and The TJX Companies (NYSE: TJX) saw stock levels improve.

“On the freight front, we’ve taken a number of actions to ready ourselves for the holiday selling period, including adjusting our order in times, we chartered our own ocean vessel and we’ve been purchasing at market rate capacity to make sure we have enough ocean freight to move goods,” said Michael Hartshorn, COO of Ross Stores, on the company’s quarterly call.

The actions resulted in 160 bps of gross margin pressure due to higher domestic and ocean freight costs.

The pull forward improved Ross Stores’ inventory-sales spread by 1,500 bps compared to last year, but the company is operating at a 1,600-bp deficit compared to the same period in 2019.

The TJX Companies, the parent company of T.J. Maxx, Marshalls and HomeGoods, recorded 160 bps of incremental freight expense in the quarter as it stocked up for the holiday season. The expectation is that number will increase by another 80 to 90 bps in the fiscal fourth quarter, which has seen mid-teen sales growth so far when compared to the same period in 2019.

The recovery in apparel lagged broader retail improvement as consumers were buying general merchandise and household goods over clothing well into the pandemic. Also, many retailers in the group have been rightsizing merchandise and trimming vendor lists to align with winning brands, which has added to inventory headwinds.

“Our business has been impacted by extended transit times, resulting in inventory receipt delays and significantly higher transportation costs,” said Michelle Gass, Kohl’s CEO. “The most visible evidence of this can be seen in our inventory level at the end of Q3, down 25% on a two-year basis.”

Kohl’s (NYSE: KSS) entered the year with the plan to lower inventory to improve margins and inventory turns but “our levels remain below that original plan,” Gass said. Inventory available for sale remains depressed, most notably in Kohl’s women’s lines, as items stuck in transit are “up quite substantially.”

While partly strategic, Kohl’s inventory reductions have resulted in stock levels trailing sales by 1,450 bps over last year and 2,500 bps over the last two years. “The industrywide supply chain challenges continue to impact our ability to rebuild inventory to desired levels,” Kohl’s CFO Jill Timm commented to analysts.

Gass asserted the company is “well-positioned for the holiday season with fresh receipts continuing to flow to support anticipated customer demand.” Guidance calls for fourth-quarter sales to increase by low double digits, but gross margins will be pressured roughly 350 bps in the fourth quarter compared to 2019. The bulk of cost pressure is tied to higher freight costs, surcharges and e-commerce fulfillment expenses.

Broader retail sales, inventory data tell the same story

The retailers’ inventories-to-sales ratio continues to bobble along the bottom, according to the latest Census Bureau data. The metric stood at 1.09x in September, a second straight monthly decline and largely rangebound since hitting a record low in April (1.07x). The metric shows retailers have just enough inventory on hand to cover a month of sales.

Pre-pandemic, the ratio was hovering around 1.45x.

Census Bureau data also showed retail and food services sales increased 1.7% from September to October on a seasonally adjusted basis, 16.3% higher year-over-year. Those growth rates accelerated 90 bps and 200 bps, respectively, from September’s increases as consumers got an early start on holiday spending.

The National Retail Federation said its core retail sales number, which excludes sales from auto dealers, gas stations and restaurants, was up by the same amount sequentially in October and 10.8% higher on an unadjusted basis year-over-year.

The “numbers show that consumers are getting a jump on their holiday shopping,” Matthew Shay, NRF president and CEO, commented on the report. “We continue to urge consumers to shop early and shop safely, and we fully expect this holiday season to be one for the record books.”

The group’s forecast calls for sales during the holiday season, which it defines as all of November and December, to increase 8.5% to 10.5% year-over-year. A recent survey conducted by the organization showed 46% of consumers polled started their holiday shopping earlier than they normally do and had completed 28% of their planned holiday spending by early November.

The NRF’s full-year 2021 forecast calls for core retail sales to increase between 10.5% and 13.5% year-over-year to roughly $4.5 trillion.

Even if year-over-year comps dip, freight is still flowing near a record pace

There’s no sign of a letup … yet.

The consumer still appears strong and willing to buy, and people are reentering the workforce. Chinese production is largely back online after factories shut down recently due to power outages, which stem from issues sourcing coal.

The NRF’s container forecast calls for twenty-foot equivalent units to continue at a record pace.

November and December are forecast to increase by more than 3% compared to last year’s elevated volumes. January (+7.6%), February (+7%) and March (-4.1%) round out the group’s monthly forecasts. Even if container flows dip into the red on a year-over-year comparison, that’s still in relation to what will be a record in 2021 — 26 million TEUs, 17.9% higher year-over-year.

At some point the consumer’s purse strings will tighten and freight demand and supply chain congestion will ease.

Spending in 2022 will face difficult comps as COVID-related stimulus, additional unemployment benefits and sign-on and merit bonuses go away. Commerce Department data shows that the personal saving rate, which soared above 30% at the onset of COVID as stimulus dollars began to flow and consumers couldn’t go out and spend them due to lockdowns, has already retreated to pre-pandemic levels as artificial income sources dissipate.

While the macroenvironment searches for whatever the new normal is next year, there appears to be a lengthy tail to this inventory replenishment/freight cycle. Consumer demand hasn’t softened, merchandise levels remain historically low and incremental transportation capacity isn’t coming online, meaning current freight market fundamentals likely hold well into 2022.

Javier

I wish we had more freight in FL, it’s very slim and hard to move around with decent rates and more if you have many reefers from the side origin, Miami!

Marie Krueger

I’ve made $84,000 so far this year working online and I’m a full time student. I’m using an online business opportunity I heard about and I’ve made such great money. MMn It’s really user friendly and I’m just so happy that I found out about it. The potential with this is endless.

Here’s what I do…>>>>> http://www.EarnApp3.com