Editor’s Note: This is Part 1 of a two-part series on preparing for International Roadcheck Week. Part 2, which published on Wednesday, looks at the top 10 things fleets can do today to prepare their equipment and drivers for clean inspections. You can read Part 2 here.

After a COVID-19-related delay last year that pushed the Commercial Vehicle Safety Alliance’s (CVSA) International Roadcheck Week to September in 2020, the annual 72-hour North American safety blitz has returned to its regular spring timeslot in 2021. CVSA has set the enforcement initiative for May 4-6 this year, and once again, fleets and drivers need to be prepared.

Like previous years, CVSA has announced areas of focus that inspectors will pay particular attention to, and this year it is lighting and hours of service (HOS). Still, drivers and fleets should remember that inspectors conducting a Level I inspection will scrutinize all aspects of the operation that fall within the 37-point inspection, J. J. Keller & Associates warned.

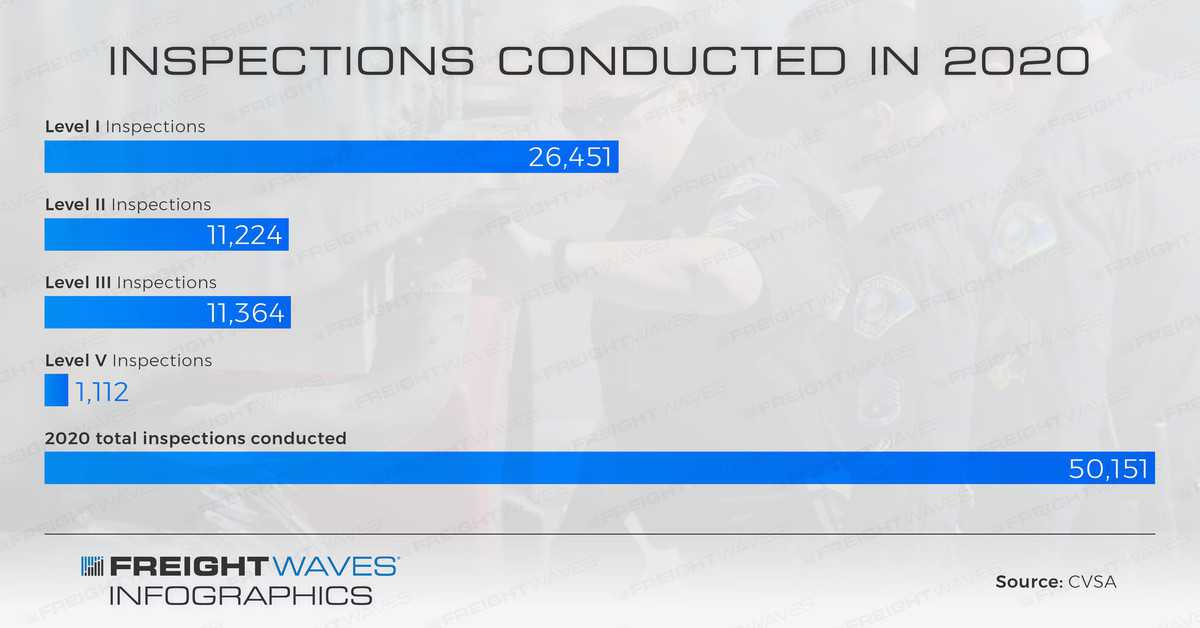

Roadcheck inspectors conducted 25% fewer inspections compared to 2019, although there was a 3% increase to 20.9% of vehicles placed out of service (OOS) and more than 3,200 drivers were placed out of service. Not surprisingly, hours-of-service violations were the reason for 35% of those drivers being placed OOS.

On the vehicle, “lamps inoperable” (49 CFR §393.9) was the top violation, as it is most years. Last year, that issue accounted for 12% of vehicle violations.

The top vehicle OOS violations were brake systems (25.8%), tires (19%), lights (13.5%), cargo securement (12.9%) and brake adjustment (12.8%).

According to J. J. Keller, Roadcheck Level I inspections are no different from any other Level I inspection during the course of the year, so fleets and drivers should be prepared. But many are not.

Following HOS violations, the top driver OOS violations were “other,” such as moving violations, cell phone use, etc. (21.8%), wrong class license (21.2%), false logs (14%) and suspended license (4.3%).

“As with most vehicle violations found during any roadside inspection, most violations caught during Roadcheck could have been found during routine maintenance and inspections,” Daren Hansen, senior editor for transportation at J. J. Keller, said. “A broken or obscured light is obviously one of the most visible defects a vehicle can have. Inspectors can spot a broken lamp a mile away, so it’s no surprise that it tops the annual list of common roadside violations.”

Both fleets and drivers should prepare checklists prior to Roadcheck. These checklists should be part of a complete safety program that can reduce violations and improve fleet safety throughout the year.

In Part 2 of the series, we will look at what fleets and their technicians can do to ensure their vehicles and drivers are prepared for Roadcheck. You can read that here. Drivers, though, also play an important role in the process. Most of the OOS violations for drivers are preventable with proper training and adherence to policies and procedures. According to Daren Hansen, senior editor for transportation at J. J. Keller, these are the top five steps drivers can take daily to improve their chances of a violation-free inspection process.

- Mental prep: Inspections will be smoother if drivers are mentally prepared to cooperate, follow the officer’s instructions, and are professional, polite and courteous during the greeting and interview, answering the officer’s questions truthfully.

- Physical prep: Never drive when you are too ill or fatigued to drive safely, or after using drugs or alcohol.

- Paperwork: Have all required paperwork organized and available for inspection. This includes a valid license, current medical card, load documentation, etc. Know where to find the company/vehicle credentials.

- HOS: Use the right kind of log (ELD or paper log or time record) and keep it up to date throughout the day. Know what to present and transfer for enforcement. If using an ELD, make sure you have all required instructions and blank paper logs.

- Vehicle: Perform daily and en-route inspections, paying special attention to brakes, lights, tires and cargo securement. Clean lights and reflective tape as needed to ensure visibility and carry spare fuses and bulbs.

J. J. Keller offers a complete driver roadside inspection checklist, including how to effectively communicate with enforcement officers.

Roadcheck inspections present a disruption to a driver’s day, but with proper preparation and focus, drivers can get through the process violation-free and be back on their way.