While I was writing this commentary on March 3, 2020, the United States Federal Reserve took the emergency step of cutting its benchmark rate by 0.5% as it attempted to head off risks to the economy. You can read about the action in these statements issued on the Fed’s website:

Some media outlets described the rate cut as the steepest since the financial crisis.

On March 2, the Wall Street Journal published Apple Bet Everything on China. Then Coronavirus Hit. While the article focuses on Apple, it highlights the issues that senior executives of other large multinational companies must grapple with as the world awakes to the reality of COVID-19, and the impact that such exogenous variables have on supply chains.

Before that, on February 18, 2020, Professor Yossi Sheffi of MIT penned an op-ed in the Journal’s Logistics Report; Commentary: Supply-Chain Risks From the Coronavirus Demand Immediate Action, in which he argues that companies must act quickly to mitigate the risks presented by the outbreak of COVID-19.

Moreover, it is nearly impossible to avoid mention of supply chain risk if you follow the news. In fact, supply chain risk featured prominently in the press conference, and the news reports, immediately following the emergency action by the Fed, with Fed Chairman Jerome Powell stating, “We do recognize a rate cut will not reduce the rate of infection, it won’t fix a broken supply chain.”

(Photo credit: Federal Reserve Bank)

Defining the problem – what is supply chain risk?

Companies build supply chain networks in order to enable them to make and distribute the products or services that they sell to their customers. Supply chain risks are any risks that make it impossible for companies to satisfy demand from their customers. This means that supply chain risk is a form of operational risk, except that while we think of operational risk as being within the confines of a specific company, we typically think of supply chain risk as existing outside the walls of a specific company, but within its network of suppliers and business partners. The article about Apple highlights how much manufacturing has become concentrated in China, not just for Apple but for many other large multinational corporations, and even for entire industries.

We can think of supply chain risks in three categories – global, systemic and unique. A global risk represents the probability of an event that knocks out supply chains across industries and geographical boundaries around the world. A systemic risk is much more limited, affecting the entire supply chain of just one company or affecting supply chain operations in just one country, or just one region of the world. A unique supply chain risk is even more limited than a systemic risk, because a unique supply chain risk is limited to just one node or just one participant, or just one small cluster of nodes in a company’s supply chain.

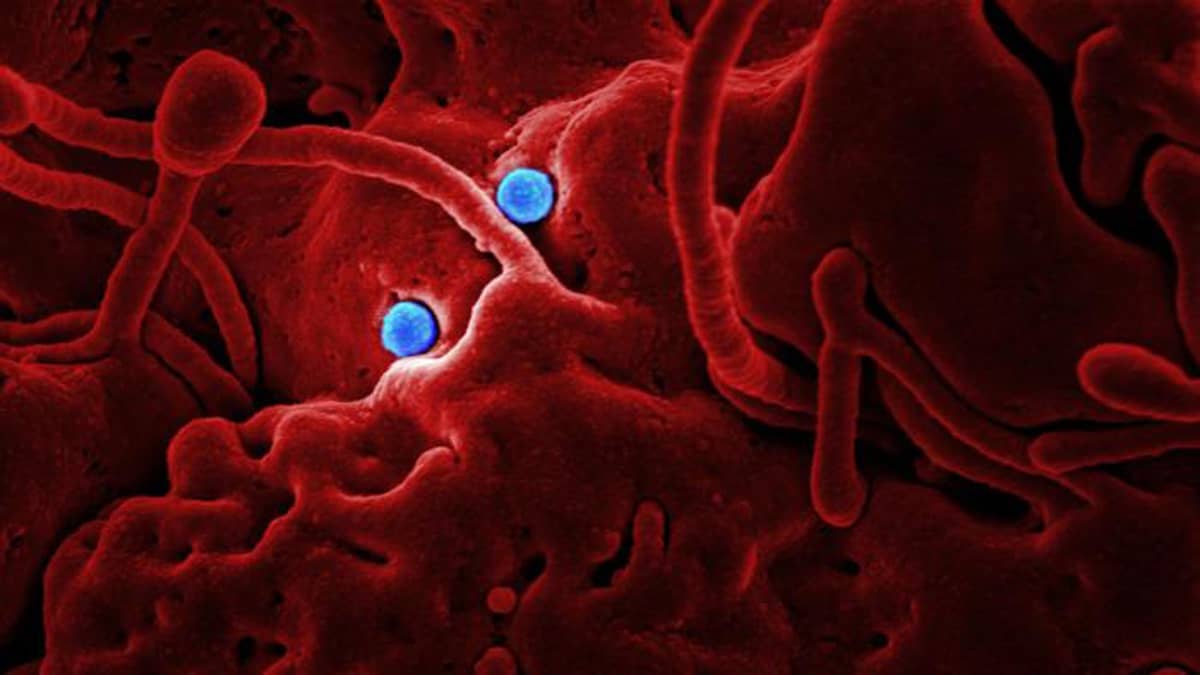

(Photo credit: Centers for Disease Control and Prevention)

As you might guess, part of the apprehension surrounding COVID-19 is that, for most people alive today, this is the first time that they are experiencing an event that has the potential to impair the smooth operation of supply chains all over the world. It is the first time that people who ordinarily do not have to worry about supply chains have been forced to think about what they will do if the daily necessities they have come to rely on are no longer available because of a supply chain disruption. COVID-19 has made supply chains everyone’s business.

What type of supply chain network is your company building?

In their book The Starfish and The Spider, Ori Brafman and Rob Beckstrom describe two types of networks. The spider describes a highly centralized network, one that collapses and dies if its head is cut off. The starfish describes a decentralized network, one that is capable of regeneration and restrengthening when any one of its nodes is destroyed. In a world that is likely to become more volatile, uncertain, complex and ambiguous, the ability to build supply chain networks that continue to improve in the face of internal and external shocks is going to become a source of competitive advantage.

As recently as a decade ago, executives would be forgiven for arguing that they had no alternatives to highly centralized supply chain networks. Given the advances in digital technologies, that excuse is no longer valid. Moreover, 2020 marks a watershed moment in how we all think about supply chain risk and how corporate executives think about managing the risks inherent in their supply chain.

If you are a team working on software products to help companies manage supply chain risk, we’d love to tell your story in FreightWaves. I am easy to reach on LinkedIn and Twitter. Alternatively, you can reach out to any member of the editorial team at FreightWaves at media@freightwaves.com.