Last fall, the North American Council for Freight Efficiency (NACFE) released the initial results of its Run on Less challenge, with the seven fleets involved achieving an average of 10.1 mpg.

The study, done in conjunction with the Carbon War Room and sponsors Shell and PepsiCo, commissioned a group of truck drivers – ranging from an owner-operator to fleets with 7,000-plus trucks – to track their mileage during their regular daily duty cycles, which included 31 of 99 total days at operating at over 65,000 lbs., as well as trucks that drove with headwinds and tailwinds from Hurricanes Harvey and Irma. All the trucks had different specs. According NACFE executive director Mike Roeth, the only real requirement was that the technologies used on the trucks needed to be commercial available.

The trucks in the study averaged 10.1 mpg overall, with 12.8 the highest individual mpg and three different trucks posting days over 12.5 mpg. The lowest mpg from a truck was 7.1 on one of the days, and the average for all lowest mpgs throughout the Run was 8.8. Collectively, the trucks traveled 50,107 miles and saved 2,877 gallons of fuel and $7,183 over the national fleet-wide average of 6.4 mpg.

The seven fleets involved in the study were: Albert Transport Inc., PepsiCo’s Frito-Lay division, Hirschbach, Mesilla Valley Transportation, Nussbaum Transportation, Ploger Transportation, and U.S. Xpress. The trucks operated over a three-week period.

At this week’s American Trucking Associations’ Technology & Maintenance Council Annual Meeting & Transportation Technology Exhibition in Atlanta, NACFE released a more detailed look at the findings from the study.

“We considered it to be a pretty good success, so we’re thinking about a Run on Less 2,” Roeth said. He added that NACFE is looking at other segments for a Run on Less 2 as well as deeper dive and more data collection into some of the variables, such as weather conditions, that affected the trucks to gain better insights into their impacts. He stressed that there has been no final decision made on a second Run, though.

Among the key takeaways from the initial event was that 10 mpg is achievable in real-world operation, but it requires some work and luck as weather conditions play a role. Telematics reports and data-logging, though, are “worthwhile investments.

“Run on Less demonstrated that 10.1 mpg is possible in real-world applications,” said Mike Roeth, executive director of NACFE. “The results are now detailed, and I challenge fleets to take advantage of available fuel-saving technologies, manufacturers to continue to ramp up their efforts in developing fuel-efficient products and other industry stakeholders to support them in the work of raising the average fuel economy of all fleets.”

NACFE said the seven trucks involved averaged 10.1 mpg over the 17 days of the Run compared to a national average of 6.4 mpg for the over-the-road tractor-trailer population. The trucks covered a total of 50,107 miles at an average gross weight of 55,498 lbs. and totaled 543,903 feet in elevation gain while dealing with various weather conditions including the effects from Hurricanes Harvey and Irma.

“The 10 mpg truck does happen in the real world,” he said. “It does happen hauling goods, and it doesn’t have to be running empty downhill.”

The overall average speed during the Run was 54 mph. You can download the full results here. Also available is all the data from the run so fleets can parse through the information.

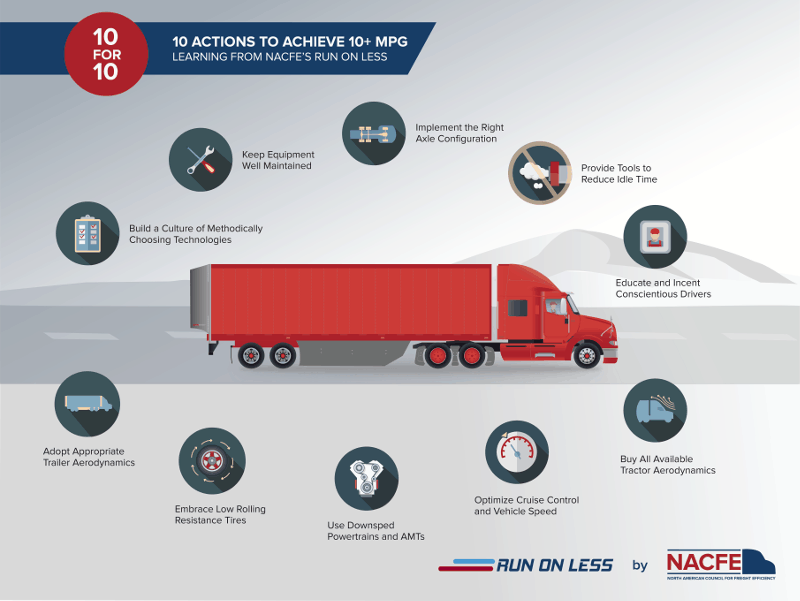

Based on its deeper data dive, NACFE is making recommendations for fleets that want to achieve higher mpg. These include:

1. Use Downsped Powertrains and AMTs. It is important to use automated manual transmissions that enable other technologies such as downspeeding, NACFE said. The duty cycle is key to these choices and, in particular with downspeeding, buyers should only apply the most aggressive downspeeding to tractors with high average speed (mph) where the amount of starts and stops are low.

2. Educate and Incent Conscientious Drivers. Run on Less benefited by having the trucks operated by some of the most proficient drivers on the road. Hiring, educating, and incentivizing drivers for the best fuel efficiency possible is a critical part of a successful fuel management system.

3. Buy All Available Tractor Aerodynamics. Fleets should start their specification process with all available sleeper tractor aerodynamics. NACFE has found that tractor aerodynamics have a very high ROI for line-haul applications and fleets should only remove items if they suffer frequent damage in their specific operation.

4. Adopt Appropriate Trailer Aerodynamics. Fleets should address trailer aerodynamics in relation to the side, rear, and front (the tractor-to-trailer gap) and adopt the most appropriate technologies depending on routes, drivers, maneuverability, etc.

5. Optimize Cruise Control and Vehicle Speed. Fleets should maximize the parameter settings for cruise control to gain the most fuel savings. While a slower speed burns less fuel, there may be times when a faster speed can get a trucker more revenue. Thus the conditions dictate whether it make more sense economically to drive faster and burn more fuel.

6. Keep Equipment Well Maintained. The technologies employed on tractors and trailers work best when the trucks are well maintained. It is important to employ solid maintenance practices and utilize technology to help the equipment run as it is intended (e.g., automatic tire inflation on trailers, use of low-viscosity lubrication, alignment, replacing or cleaning all filters, etc.).

7. Implement the Right Axle Configuration. Fleets should use the correct axle configuration for the job, depending on the payload, speed, maneuverability, fleet practices such as tire management, and even resale value if the asset will be sold before its useful life is exhausted.

8. Embrace Low Rolling Resistance Tires. Low rolling resistance tires are critical for a fleet to get high mpg, but the most fuel-efficient tires are not right for every fleet, application, or region. A productive tire purchase and management process takes focus but will pay off.

9. Provide Tools to Reduce Idle Time. Drivers should shut the truck off whenever and wherever possible and use technology and engine parameter settings to reduce idle time.

10. Build a Culture of Methodically Choosing Technologies. Fleets should have a process to constantly monitor, adjust, and act upon new technology opportunities. Best practices include comprehensive understanding of the performance, either by testing or through industry involvement; robust payback or return on investment analyses; and supplier selection.

Roeth also mentioned that NACFE would begin to start issuing “Guidance Reports” in addition to its Confidence Reports. These Guidance Reports will focus on evolving technologies, and unlike the Confidence Reports which attempt to quantify the impact of technologies, the Guidance Reports will try to shed additional light on emerging and evolving technologies. One on electric trucks will be coming soon and autonomous vehicles will also appear in a future report.

Stay up-to-date with the latest commentary and insights on FreightTech and the impact to the markets by subscribing.